The legal definition stipulates that;

- Effluent as industrial effluent, mixed effluent or sewage.

- Industrial Effluent is defined as any wastewater produced by reasons of production activities.

- Sewage is defined as any wastewater containing animal and vegetable matter in solution or suspension. It simply means faecal or urinal discharges.

- Definasi yang telah ditetapkan dibawah undang-undang;

- Effluent adalah effluent industri, effluent bercampur atau kumbahan.

- Effluen industri adalah air buangan yang dilepaskan diatas sebab-sebab aktiviti pemerosesan/pengeluaran.

- Kumbahan adalah air buangan yang berpunca dari sisa manusia.

Written notification for new source and upgrade existing;

Professional engineer undertakes design & construction;

Build and operate as design;

New parameters: e.g. Silver, Aluminium, Selenium, Barium, Fluoride, Formaldehyde, Ammoniacal Nitrogen and Color;

COD varies for specific industry – more achievable;

Full-time competent person – trained and certified by DOE;

Performance monitoring is mandatory;

Best management practices be in practice;

By-pass & dilution is prohibited;

Spills, accidental release or leakage – 6 hours to DOE;

Prohibition order for continued incompliance;

Direct judicial action under the regulation enabled;

Legal liability under Section 25, EQA 1974 - not discussed here.

Water Pollution; overview of significant parameters:

|

| Nature of effluent and sewage: inorganic, organic & inorganic, organic; |

Cadmium – used in manufacture of batteries, paints, plastics, plating of iron products e.g. bolts, nuts, as anti-corrosion agent. Health impact upon human – brittle bones & intense pain, high blood, sterility among males, kidney and flu-like disorders. This soft, bluish-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Similar to zinc, it prefers oxidation state +2 in most of its compounds and similar to mercury it shows a low melting point compared to transition metals. Cadmium and its congeners are not always considered transition metals, in that they do not have partly filled d or f electron shells in the elemental or common oxidation states. The average concentration of cadmium in the Earth's crust is between 0.1 and 0.5 parts per million (ppm). It was discovered in 1817 simultaneously by Stromeyer and Hermann, both in Germany, as an impurity in zinc carbonate.

Cadmium occurs as a minor component in most zinc ores and therefore is a byproduct of zinc production. It was used for a long time as a pigment and for corrosion resistant plating on steel while cadmium compounds were used to stabilize plastic. With the exception of its use in nickel-cadmium batteries and cadmium telluride solar panels, the use of cadmium is generally decreasing in its other applications. These declines have been due to competing technologies, cadmium’s toxicity in certain forms and concentration and resulting regulations.[2] Although cadmium has no known biological function in higher organisms, a cadmium-dependent carbonic anhydrase has been found in marine diatoms.

Chromium – used in manufacture of alloys, refractories, catalysts, chromic oxide, and chromate salts for the plating industry and paint manufacturing. Chromate poisoning – skin disorders and liver damage – oncogenic i.e. carcinogenic. Virtually all chromium ore is processed via hexavalent chromium, specifically the salt, sodium dichromate. Approximately 136,000,000 kilograms (300,000,000 lb) of hexavalent chromium were produced in 1985.[1] Other hexavalent chromium compounds are chromium trioxide and various salts of chromate and dichromate. Hexavalent chromium is used for the production of stainless steel, textile dyes, wood preservation, leather tanning, and as anti-corrosion and conversion coatings as well as a variety of niche uses. Chromium hexavalent (CrVI) compounds, often called hexavalent chromium, exist in several forms. Industrial uses of hexavalent chromium compounds include chromate pigments in dyes, paints, inks, and plastics; chromates added as anticorrosive agents to paints, primers, and other surface coatings; and chromic acid electroplated onto metal parts to provide a decorative or protective coating. Hexavalent chromium can also be formed when performing "hot work" such as welding on stainless steel or melting chromium metal. In these situations the chromium is not originally hexavalent, but the high temperatures involved in the process result in oxidation that converts the chromium to a hexavalent state.(29 CFR OSHA General Industry 1910)Hexavalent chromium is recognized as a human carcinogen via inhalation.[2] Workers in many different occupations are exposed to hexavalent chromium. Problematic exposure is known to occur among workers who handle chromate-containing products as well as those who perform welding, grinding, or brazing on stainless steel.[2] Within the European Union, the use of hexavalent chromium in electronic equipment is largely prohibited by the Restriction of Hazardous Substances Directive.

Copper – commonly used as Copper Sulphate to control growth of algae in water supply reservoirs – near 1.0mg/L may be toxic to some fish.

Lead – used in service pipes, paints for interior décor, previously in petrol – causes brain and kidney damage. Lead is a soft, malleablepoor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed to air. Lead has a shiny chrome-silver luster when it is melted into a liquid. Lead is used in building construction, lead-acid batteries, bullets and shots, weights, as part of solders, pewters, fusible alloys and as aradiation shield. Lead has the highest atomic number of all of the stable elements, although the next higher element, bismuth, has ahalf-life that is so long (much longer than the age of the universe) that it can be considered stable. Its four stable isotopes have 82 protons, a magic number in the nuclear shell model of atomic nuclei.

Lead, at certain exposure levels, is a poisonous substance to animals. It damages the nervous system and causes brain disorders. Excessive lead also causes blood disorders in mammals. Like the element mercury, another heavy metal, lead is a neurotoxin that accumulates both in soft tissues and the bones. Lead poisoning has been documented from ancient Rome, ancient Greece, and ancient China.

Mercury – used in amalgams, scientific equipments, batteries, arc lamps, extraction of gold & silver, electrolytic production of chlorine, its salts – used as fumigants in herbicides & insecticides. Also used as antifoulants in ship paints and mildew proofing of canvas. In 1950s – Minamata Bay incident – chemical plant – effluent – sea food intake – 111 cases – 43 died – babys from afflicted mother – congenitals defects. Lake St. Clair – US & Canada – Fish – from Chlor-alkali industry – methylated mercury – produced by bacterial action in bottom muds in anaerobic condition. It is also known as quicksilver ( /ˈkwɪksɪlvər/ ) or hydrargyrum ( /haɪˈdrɑrdʒɨrəm/), from "hydr-" water and "argyros" silver. Mercury is the only metal that is liquid at standard conditions for temperature and pressure; the only other element that is liquid under these conditions is bromine. With a freezing point of −38.83 °C and boiling point of 356.73 °C, mercury has one of the narrowest ranges of its liquid state of any metal. A heavy, silvery d-block metal, mercury is the only metallic element that is liquid at room temperature and standard pressure, with elements such as caesium, francium, gallium, and rubidium being liquid just above room temperature or at non-standard pressure.[1][2][3]

Mercury occurs in deposits throughout the world mostly as cinnabar (mercuric sulfide). The red pigment vermilion is mostly obtained by reduction from cinnabar. Cinnabar is highly toxic by ingestion or inhalation of the dust. Mercury poisoning can also result from exposure to water soluble forms of mercury (such as mercuric chloride or methylmercury), inhalation of mercury vapor, or eating seafood contaminated with mercury. Mercury is used in thermometers, barometers, manometers, sphygmomanometers, float valves, some electrical switches, and other scientific apparatus, though concerns about the element's toxicity have led to mercury thermometers and sphygmomanometers being largely phased out in clinical environments in favor of alcohol-filled, digital, or thermistor-based instruments. It remains in use in scientific research applications and in amalgam material for dental restoration. It is used in lighting: electricity passed through mercury vapor in a phosphor tube produces short-wave ultraviolet light which then causes the phosphor to fluoresce, making visible light.

Nickel & Cobalt – used in electroplating – effluent – aquatic environment – oncogenic.

Silver – used in electroplating – usually recovered – expensive – silver poisoning – darkening of skin & eyes.

Arsenic (non-metal) – used in plating operations, refinery, coal coking – widely distributed in natural waters – arsenic eaters – toxic level in human is erratic – suspected to be oncogenic. Selenium – used in manufacture of electrical components, photoelectric cells & rectifiers – oncogenic to human: with poor evidence as some test showed anti-oncogenic – causes improper bone formation in animals i.e. ‘alkali disease’ and ‘blind staggers’.

Overview of wastewater to sludge pictorial illustration;

Ø General scope based treatment objectives;

General scope based on treatment schemes:

Detail scopes of primary, secondary & tertiary treatment

Primary Treatment;

- Primary treatment; raw effluent or influent – often contains other contaminant or foreign matters in coarse or bigger sizes e.g. grass-cut debris, fibres of fruit and pulps, scum of fatty matters, resins, adhesives, etc. that may upset the WWTP’s system, such as clogging pumps, valves and pipes.

- Secondary treatment; e.g. in biological systems –anaerobic or aerobic decomposition of organic matters to ideally H2O and CO2 plus dead cells in sludge forms that settles in clarifiers. In chemical treatment – inorganic pollutants removed by coagulation & flocculation – settles – sludge. Tertiary treatment – e.g. removal of dissolved solids, colour, odour, pathogenic organisms, inorganics not removable by conventional chemical treatment, etc. including dewatering and further treatment of sludge.

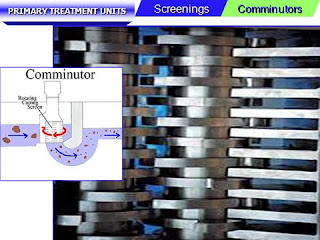

In some plants, shredding devices are installed after the bar screen or as alternatives to screening. Shredding devices reduce solids to a size that can enter the plant without causing mechanical problems or clogging. The most common shredder is the comminutor. In this device all of the wastewater flow passes through the grinder assembly. The grinder consists of a screen or slotted basket, a rotating or oscillating cutter and a stationary cutter. Solids pass through the screen and are chopped or shredded between the two cutters. The comminutor will not remove solids that are too large to fit through the slots, and it will not remove floating objects. The materials must be removed manually.

Comminutors can be used in wastewater treatment to cut up and grind the coarse solids into smaller sizes so that this will eliminate the problems caused towards downstream operations especially clogging happening in pumps. Different from bar racks and coarse screens, it does not involve having to remove any type of solid out from the flow system and thus void the necessity of messy jobs having to clean and handle on solid waste disposal. Its use and application is particular important in treatment plants located in cold climates areas whereby use of comminutors means there will not be any issue with collected waste becoming trapped on freezing screens.

Usually a preliminary study will be carried out to determine what types of solids are normally present and where the wastewater come from and especially from which industry that generates it. Normally based on this information, the manufacturer will build and sized it up accordingly to handle the incoming flow. A vertical rotating system is very common and a typical installation will usually have a revolving drum driven by a motor and inside it, there are multiple sets of moving teeth and shearing bars to tear apart the solids as it gets carried together with the wastewater flow. Other designs of comminuting devices will have individual circular screen rotating in the opposite direction and as large solids passes through, it will be subjected to the shearing force exerted by both the outer and inner screens. The small clearance between the moving and stationary screen will tear apart the solids reducing its size before it can pass through.

Grit remover;

Most systems these days are built right after the grit chamber in order to prolong the life of the moving parts and to reduce wear and tear occurring on the surfaces. Certain wastewater treatment plant will have both manual bar screens and the comminutors working together in parallel and depending on the incoming flow rates; wastewater can be diverted going to either one of it through bypass lines. Other problems related to its application is on the maintenance aspect as high wear and tear will often require frequent changing of the moving parts.

Most of the time, this can be avoided if there are also rock traps built in at the upper channel to prevent material from damaging the cutting blades. Head loss is also another issue as the wastewater passes through the comminutor and thus the overall design of the system has to take this into consideration. The best approach is to consult the manufacturers and bring up this issue and highlight it as part of the requirements. The first step in the treatment of wastewater is known as Preliminary Treatment, which screens out, grinds up, or separates debris in the wastewater. Sticks, rags, large food particles, sand, gravel, toys, plastics, and other objects are removed at this stage to conserve valuable space within the treatment processes and to protect pumping and other equipment from clogs, jams or excessive wear. Treatment equipment such as bar screens, comminutors (a large version of a garbage disposal that shreds material), and grit chambers are used on the wastewater as it first enters a treatment plant. The collected debris is usually disposed of in a landfill. In this lesson we will describe and discuss each of these processes and their importance in the treatment process.

Most systems these days are built right after the grit chamber in order to prolong the life of the moving parts and to reduce wear and tear occurring on the surfaces. Certain wastewater treatment plant will have both manual bar screens and the comminutors working together in parallel and depending on the incoming flow rates; wastewater can be diverted going to either one of it through bypass lines. Other problems related to its application is on the maintenance aspect as high wear and tear will often require frequent changing of the moving parts.

Most of the time, this can be avoided if there are also rock traps built in at the upper channel to prevent material from damaging the cutting blades. Head loss is also another issue as the wastewater passes through the comminutor and thus the overall design of the system has to take this into consideration. The best approach is to consult the manufacturers and bring up this issue and highlight it as part of the requirements. The first step in the treatment of wastewater is known as Preliminary Treatment, which screens out, grinds up, or separates debris in the wastewater. Sticks, rags, large food particles, sand, gravel, toys, plastics, and other objects are removed at this stage to conserve valuable space within the treatment processes and to protect pumping and other equipment from clogs, jams or excessive wear. Treatment equipment such as bar screens, comminutors (a large version of a garbage disposal that shreds material), and grit chambers are used on the wastewater as it first enters a treatment plant. The collected debris is usually disposed of in a landfill. In this lesson we will describe and discuss each of these processes and their importance in the treatment process.

Grit removal; e.g. sand, gravel, cinders, or other heavy solid materials that have subsiding velocities or specific gravities greater than the organic putrescible solids in the effluent – e.g. sugar refinery, fruit-based drinks - uses grit chambers or centrifuge.

The Grit is a general term for coarse particles. BS3405 defines grit as solid particles retained on a mesh BS sieve with pore size of 76um.

Another version where grit remover and oil interceptor is combined in a pre-treatment or primary stage. Apart from occupying less space in its built-up it allows easier maintenance. However its size and retention time is a critical factor to consider as some types of effluent are prone to biological activity, especially, an anaerobic condition towards the bottom of the tank. Suitable for effluent with high coarse and dense impurities plus oily nature e.g. palm oil, drilling mud, sugar-cane, mining, etc.

Oil interceptor;

The API separator is a gravity separation device designed by using Stokes Law to define the rise velocity of oil droplets based on their density and size. The design of the separator is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom. (Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st Edition ed.). John Wiley & Sons. LCCN 67019834.) Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment consisting usually of a dissolved air flotation (DAF) unit for further removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs).The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Any sediment slides down the topside of each parallel plate. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

CPI interceptor

In CPIs the parallel plates are corrugated (like roofing material) with the axis of the corrugations parallel to the direction of flow. The plate pack is inclined at an angle of 45° and the bulk water flow is forced downward. The oil sheet rises upward counter to the water flow and is concentrated in the top of each corrugation. When the oil reaches the end of the plate pack, it is collected in a channel and brought to the oil-water interface. For service temperatures less than 60°C, fiberglass with a steel frame is used. For service temperatures greater than 60°C, corrosion-resistant alloys or stainless steels are recommended.

The Grit is a general term for coarse particles. BS3405 defines grit as solid particles retained on a mesh BS sieve with pore size of 76um.

Another version where grit remover and oil interceptor is combined in a pre-treatment or primary stage. Apart from occupying less space in its built-up it allows easier maintenance. However its size and retention time is a critical factor to consider as some types of effluent are prone to biological activity, especially, an anaerobic condition towards the bottom of the tank. Suitable for effluent with high coarse and dense impurities plus oily nature e.g. palm oil, drilling mud, sugar-cane, mining, etc.

Oil interceptor;

The API separator is a gravity separation device designed by using Stokes Law to define the rise velocity of oil droplets based on their density and size. The design of the separator is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom. (Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st Edition ed.). John Wiley & Sons. LCCN 67019834.) Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment consisting usually of a dissolved air flotation (DAF) unit for further removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs).The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Any sediment slides down the topside of each parallel plate. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

CPI interceptor

In CPIs the parallel plates are corrugated (like roofing material) with the axis of the corrugations parallel to the direction of flow. The plate pack is inclined at an angle of 45° and the bulk water flow is forced downward. The oil sheet rises upward counter to the water flow and is concentrated in the top of each corrugation. When the oil reaches the end of the plate pack, it is collected in a channel and brought to the oil-water interface. For service temperatures less than 60°C, fiberglass with a steel frame is used. For service temperatures greater than 60°C, corrosion-resistant alloys or stainless steels are recommended.

Grease traps (also known as grease interceptors, grease recovery devices and grease converters) are plumbing devices designed to intercept most greases and solids before they enter a wastewater disposal system. septic tanks and treatment facilities to form a floating scum layer. anaerobic digestion process. However, very large amounts of oil from food production in kitchens of factory canteens and restaurants can overwhelm the septic tank or treatment facility, causing a release of untreated sewage into the environment. Also, high viscosity fats and cooking greases such as lard solidify when cooled, and can combine with other disposed solids to form blockages in drain pipes.

Common wastewater contains small amounts of oils which enter into

This scum layer is very slowly digested and broken down by microorganisms in the

Common wastewater contains small amounts of oils which enter into

Equalization; the EQ Tank

Equalization Tank

Description: Flow equalization simply is the damping of flowrate variations so that a constant or nearly constant flowrate is achieved. The principal benefits that are cited as deriving from application of flow equalization are as follows:

· Biological treatment is enhanced, because shock loadings are eliminated or can be minimized, inhibiting substances can be diluted, and pH can be stabilized The effluent quality and thickening performance of secondary sedimentation tanks following biological treatment is improved through constant solids loading.

· Effluent - filtration surface - area requirements are reduced, filter performance is improved, and more uniform filter - backwash cycles are possible Equalization Tank

Description: Flow equalization simply is the damping of flowrate variations so that a constant or nearly constant flowrate is achieved. The principal benefits that are cited as deriving from application of flow equalization are as follows:

· Biological treatment is enhanced, because shock loadings are eliminated or can be minimized, inhibiting substances can be diluted, and pH can be stabilized The effluent quality and thickening performance of secondary sedimentation tanks following biological treatment is improved through constant solids loading.

· In chemical treatment, damping of mass loading improves chemical feed control and process reliability

Volume Requirements for Equalization Tank : The volume required for flowrate equalization is determined by using an inflow mass diagram in which the cumulative inflow volume is plotted versus the time of day. The average daily flowrate, also plotted on the same diagram, is the straight line drawn from the origin to the endpoint of the diagram (see figure shown below).

In practice, the volume of the equalization tank will be larger than that theoretically determined to account for the following factors:

Continuous operation of aeration and mixing equipment will not allow complete drawdown, although special structures can be built

Volume must be provided to accommodate the concentrated plant recycle streams that are expected, if such flows are returned to the equalization tank (a practice that is not recommended because of the potential to create odour) Some contingency should be provided for unforeseen changes in diurnal flow

Operational Data of the Equalization Tank

|

|||||

Hours

|

Inflow (m3)

|

Outflow (m3)

|

Cumulative Inflow (m3)

|

Cumulative Outflow (m3)

|

Cumulative Difference

(m3)

|

00 - 01

|

0.00

|

8.33

|

0.00

|

8.33

|

- 8.33

|

01 - 02

|

0.00

|

8.33

|

0.00

|

16.66

|

- 16.66

|

02 - 03

|

0.00

|

8.33

|

0.00

|

24.99

|

- 24.99

|

03 - 04

|

0.00

|

8.33

|

0.00

|

33.32

|

- 33.32

|

04 - 05

|

0.00

|

8.33

|

0.00

|

41.65

|

- 41.65

|

05 - 06

|

0.00

|

8.33

|

0.00

|

49.98

|

- 49.98

|

06 - 07

|

0.00

|

8.33

|

0.00

|

58.31

|

- 58.31

|

07 - 08

|

0.00

|

8.33

|

0.00

|

66.68

|

- 66.68

|

08 - 09

|

17.40

|

8.33

|

17.40

|

75.01

|

- 57.61

|

09 - 10

|

26.80

|

8.33

|

44.20

|

83.34

|

- 39.14

|

10 - 11

|

23.00

|

8.33

|

67.20

|

91.67

|

- 24.47

|

11 - 12

|

19.30

|

8.33

|

86.50

|

100.00

|

- 13.50

|

12 - 13

|

13.20

|

8.33

|

99.70

|

108.33

|

- 8.63

|

13 - 14

|

15.60

|

8.33

|

115.30

|

116.66

|

- 1.36

|

14 - 15

|

23.10

|

8.33

|

138.40

|

124.99

|

+ 13.41

|

15 - 16

|

21.10

|

8.33

|

159.50

|

133.32

|

+ 26.18

|

16 - 17

|

21.10

|

8.33

|

180.60

|

141.65

|

+ 38.95

|

17 - 18

|

19.40

|

8.33

|

200.00

|

150.02

|

+ 49.98

|

18 - 19

|

0.00

|

8.33

|

200.00

|

158.35

|

+ 41.65

|

19 - 20

|

0.00

|

8.33

|

200.00

|

166.68

|

+ 33.32

|

20 - 21

|

0.00

|

8.33

|

200.00

|

175.01

|

+ 24.99

|

21 - 22

|

0.00

|

8.33

|

200.00

|

183.34

|

+ 16.66

|

22 - 23

|

0.00

|

8.33

|

200.00

|

191.67

|

+ 8.33

|

23 - 24

|

0.00

|

8.33

|

200.00

|

200.00

|

0.00

|

VEqualization

tank = 66.68 + 49.98 =

116.66 m3

Continuous Mixing in Equalization Tank...

In continuous mixing, the principal objective is to maintain the contents of a reactor of holding tank in a completely mixed state. Continuous mixing can be accomplished in a number of different ways, including; (1) in hydraulic jumps in open channels, (2) in "Venturi" flumes, (3) in pipelines, (4) by pumping, (5) with static mixers and (6) mechanical mixers. According to the literature, the completely mixed regime can be obtained in a equalization tank, by applying a power varying between 10 and 30 W / m3. Continuous mixing in the equalization tank was accomplished by a submerged mechanical mixer having a power of 4 kW.

Primary clarification; clarifier tanks

DAF can be categorized by Circular (more efficient) and Rectangular (more residence time). The former type requires just 3 minutes and the example is Wockoliver DAF system, whereas Rectangular requires 20 to 30 minutes the typical example can be syskill DAF system. One of the bigger advantage of Circular is its Spiral Scoop.

Operating Principle

Air under pressure is dissolved into water according to Henry's Law of Dissolution. Releasing the pressure back to STP via a special device creates millions of microbubbles approximately 30-100 microns in diameter. The microbubbles attach to floc in the water and float it to the surface for removal.

Features

High Loading - Rates 4-6 gpm/sf.

Reduced Chemical Comsumption - Formation of a large, rapidly settling floc is not required, saving money.

High Sludge Concentrations - Dewatering can occur without additional thickening, eliminating expensive sludge thickeners.

Rapid Start-Up - Good-quality water can be produced within 45 minutes of start-up.

Compact Design - Requires less space than conventional processes.

Onsite sewage facilities (OSSF) are recognized as viable, low-cost, long-term, decentralized approaches to sewage treatment if they are planned, designed, installed, operated and maintained properly (USEPA, 1997).

Sewage trickling filters are used in areas not serviced by municipal wastewater treatment plants (WWTP). They are typically installed in areas where the traditional septic tank system are failing, cannot be installed due to site limitations, or where improved levels of treatment are required for environmental benefits such as preventing contamination of ground water or surface water.

Sites with a high water table, high bedrock, heavy clay, small land area, or which require minimal site destruction (for example, tree removal) are ideally suited for trickling filters.

All varieties of sewage trickling filters have a low and sometimes intermittent power consumption. They can be somewhat more expensive than traditional septic tank-leach field systems, however their use allows for better treatment, a reduction in size of disposal area, less excavation, and higher density land development.

Industrial wastewater treatment trickle filters

Wastewaters from a variety of industrial processes have been treated in trickling filters. Such industrial wastewater trickling filters consist of two types:

Large tanks or concrete enclosures filled with plastic packing or other media.[1]

Vertical towers filled with plastic packing or other media.[2][3]

The availability of inexpensive plastic tower packings has led to their use as trickling filter beds in tall towers, some as high as 20 meters.[4] As early as the 1960s, such towers were in use at: the Great Northern Oil's Pine Bend Refinery in Minnesota; the Cities Service Oil Company Trafalgar Refinery in Oakville, Ontario and at a kraft paper mill.[5]

The treated water effluent from industrial wastewater trickling filters is very often subsequently processed in a clarifier-settler to remove the sludge that sloughs off the microbial slime layer attached to the trickling filter media (see Image 1 above).

Currently, some of the latest trickle filter technology involves aerated biofilters which are essentially trickle filters consisting of plastic media in vessels using blowers to inject air at the bottom of the vessels, with either downflow or upflow of the wastewater.[6]

The goal of a primary clarifier is to remove sediment by using gravity, much like the grit chambers. As the wastewater enters the tank, it allows for these larger particles to settle. This settling process is aided by the addition of chemicals. The particles and chemicals that settle to the bottom are then sent to the sludge collection well, and the wastewater continues on to activated sludge. After being screened, in one case of a sewage treatment, the wastewater enters two 45-foot diameter, 140,000-gallon tanks called clarifiers. Here the biosolids are allowed to settle to the bottom of the tank. The solids are eventually pumped out of the tank and stored for later treatment. Between 15 and 40 percent of the solids are removed at this stage, which takes about 4.5 hours.

Primary sedimentation tanks shall be designed for:

maximum surface loading of 40 m3/m2/d at peak flow,

minimum retention time of 2 hours at peak flow,

maximum weir loading of 250 m3/m/d at peak flow.

Final sedimentation tanks shall be designed for:

maximum surface loading of 35 m3/m2/d at peak flow if they are preceded by Rotating Biological Contactor (RBC) or biological filters,

maximum surface loading of 22 m3/m2/d at peak flow if they are preceded by the extended aeration process,

minimum retention time of 2 hours at peak flow.

The reduction of total BOD by different stages of the primary treatment processes should be taken as follow:

equalization tank-nil

coarse screen-nil

fine screen (max. opening 2 mm)-7.5%

primary sedimentation-30%

fine screen and primary sedimentation-30%

The net BOD load going into the subsequent biological processes should be computed accordingly.

RBC (Rotating Biological Contractor): 10 g total BOD/m2/d (i.e. per sq.m. of RBC surface) entering into the RBC or as recommended by manufacturer, whichever is smaller.

Extended aeration: 0.07 kg total BOD/kg MLSS/d and MLSS in the range between 2 000 and 3 500 mg/L

Plastic biological filter (Bio-filter): 0.5 kg total BOD/m3/d (i.e. per cu.m. of media volume) or as recommended by manufacturer, whichever is smaller.

For other biological treatment methods, such as sequential batch reactor, contact stabilization and other patented processes etc., organic loadings proposed in the design should be justified based on its previous Wastewater-Characterization-Study.

Settling

While a degree of clarification can be accomplished by subsidence (settling), most industrial processes require better quality water than can be obtained from settling only. Most of the suspended matter in water would settle, given enough time, but in most cases the amount of time required would not be practical. The time required for settling is dependent on many factors, including:

1. Weight of the particle

2. Shape of the particle

3. Size of the particle

4. Viscosity and/or frictional resistance of the water, which is a function of temperature

The settling rates of various size particles at 50 ºF (10 ºC) is illustrated in the Table that follows;

Stokes' Law

Settling velocities may be calculated from Stokes' Law.

V = 2662(S1 - S2),D2 / z

Where V = Velocity of fall (ft/sec)

D = Diameter of particle (in)

S1= Density of particle (lb/ft3)

S2= Density of fluid (lb/ft3)

z = Viscosity (centipoises)

In this equation it is assumed that the particles are spherical, failing under viscous resistance, and that they have no electrostatic charges. This is, of course, never true under actual conditions. Most suspended solids smaller than 0.1 mm found in surface waters carry negative electrostatic charges. This charge causes the particles to repel each other, increasing their stability and thus increasing their tendency to remain suspended. Chemicals are often added to water to neutralize particle charge and enhance particle settling. Chemicals used to promote suspended particle subsidence in the clarification process are commonly called coagulants; the particle charge neutralization process is called coagulation. (Reference from: GC3 SPECIALTY CHEMICALS, INC.)maximum surface loading of 40 m3/m2/d at peak flow,

minimum retention time of 2 hours at peak flow,

maximum weir loading of 250 m3/m/d at peak flow.

Final sedimentation tanks shall be designed for:

maximum surface loading of 35 m3/m2/d at peak flow if they are preceded by Rotating Biological Contactor (RBC) or biological filters,

maximum surface loading of 22 m3/m2/d at peak flow if they are preceded by the extended aeration process,

minimum retention time of 2 hours at peak flow.

The reduction of total BOD by different stages of the primary treatment processes should be taken as follow:

equalization tank-nil

coarse screen-nil

fine screen (max. opening 2 mm)-7.5%

primary sedimentation-30%

fine screen and primary sedimentation-30%

The net BOD load going into the subsequent biological processes should be computed accordingly.

RBC (Rotating Biological Contractor): 10 g total BOD/m2/d (i.e. per sq.m. of RBC surface) entering into the RBC or as recommended by manufacturer, whichever is smaller.

Extended aeration: 0.07 kg total BOD/kg MLSS/d and MLSS in the range between 2 000 and 3 500 mg/L

Plastic biological filter (Bio-filter): 0.5 kg total BOD/m3/d (i.e. per cu.m. of media volume) or as recommended by manufacturer, whichever is smaller.

For other biological treatment methods, such as sequential batch reactor, contact stabilization and other patented processes etc., organic loadings proposed in the design should be justified based on its previous Wastewater-Characterization-Study.

Settling

While a degree of clarification can be accomplished by subsidence (settling), most industrial processes require better quality water than can be obtained from settling only. Most of the suspended matter in water would settle, given enough time, but in most cases the amount of time required would not be practical. The time required for settling is dependent on many factors, including:

1. Weight of the particle

2. Shape of the particle

3. Size of the particle

4. Viscosity and/or frictional resistance of the water, which is a function of temperature

The settling rates of various size particles at 50 ºF (10 ºC) is illustrated in the Table that follows;

Stokes' Law

Settling velocities may be calculated from Stokes' Law.

V = 2662(S1 - S2),D2 / z

Where V = Velocity of fall (ft/sec)

D = Diameter of particle (in)

S1= Density of particle (lb/ft3)

S2= Density of fluid (lb/ft3)

z = Viscosity (centipoises)

Introduction

Treatment of wastewater using an oxidation ditch is relatively similar to wastewater treatment in a packaged plant. But the oxidation ditch replaces the aeration basin and provides better sludge treatment.

Treatment of wastewater using an oxidation ditch is relatively similar to wastewater treatment in a packaged plant. But the oxidation ditch replaces the aeration basin and provides better sludge treatment.

Oxidation ditch

The only pretreatment typically used in an oxidation ditch system is the bar screen. After passing through the bar screen, wastewater flows directly into the oxidation ditch.

The oxidation ditch is a circular basin through which the wastewater flows. Activated sludge is added to the oxidation ditch so that the microorganisms will digest the B.O.D. in the water. This mixture of raw wastewater and returned sludge is known as mixed liquor.

Oxygen is added to the mixed liquor in the oxidation ditch using rotating biological contactors (RBC's.) RBC's are more efficient than the aerators used in packaged plants. In addition to increasing the water's dissolved oxygen, RBC's also increase surface area and create waves and movement within the ditches. Once the B.O.D. has been removed from the wastewater, the mixed liquor flows out of the oxidation ditch. Sludge is removed in the clarifier. This sludge is pumped to an aerobic digester where the sludge is thickened with the help of aerator pumps. This method greatly reduces the amount of sludge produced. Some of the sludge is returned to the oxidation ditch while the rest of the sludge is sent to waste.

Comparison to a Packaged Plant

The treatment of wastewater in an oxidation ditch is similar to treatment in a packaged plant. The two main differences between the processes are the retention time and the type of organisms which digest the wastewater.

Retention time is much longer in an oxidation ditch. A packaged plant usually has a retention time of two to four hours while an oxidation ditch retains the wastewater for two days. Since the D.O. is higher in the oxidation ditch than in a packaged plant, a greater variety of microorganisms live in the oxidation ditch. In contrast, packaged plants usually depend upon only a few types of microorganisms to ‘eat’ the sewage.

Ammonia Removal Oxidation ditches can be set up to remove ammonia very effectively. Wastewater can be sent through two sets of ditches, each of which has a different pH. The different pH in the two ditches creates a niche for certain microorganisms. These microorganisms are very efficient at removing B.O.D and converting ammonia to nitrates. Oxidation ditches are much more efficient at ammonia removal than packaged plants.

The only pretreatment typically used in an oxidation ditch system is the bar screen. After passing through the bar screen, wastewater flows directly into the oxidation ditch.

The oxidation ditch is a circular basin through which the wastewater flows. Activated sludge is added to the oxidation ditch so that the microorganisms will digest the B.O.D. in the water. This mixture of raw wastewater and returned sludge is known as mixed liquor.

Oxygen is added to the mixed liquor in the oxidation ditch using rotating biological contactors (RBC's.) RBC's are more efficient than the aerators used in packaged plants. In addition to increasing the water's dissolved oxygen, RBC's also increase surface area and create waves and movement within the ditches. Once the B.O.D. has been removed from the wastewater, the mixed liquor flows out of the oxidation ditch. Sludge is removed in the clarifier. This sludge is pumped to an aerobic digester where the sludge is thickened with the help of aerator pumps. This method greatly reduces the amount of sludge produced. Some of the sludge is returned to the oxidation ditch while the rest of the sludge is sent to waste.

Comparison to a Packaged Plant

The treatment of wastewater in an oxidation ditch is similar to treatment in a packaged plant. The two main differences between the processes are the retention time and the type of organisms which digest the wastewater.

Retention time is much longer in an oxidation ditch. A packaged plant usually has a retention time of two to four hours while an oxidation ditch retains the wastewater for two days. Since the D.O. is higher in the oxidation ditch than in a packaged plant, a greater variety of microorganisms live in the oxidation ditch. In contrast, packaged plants usually depend upon only a few types of microorganisms to ‘eat’ the sewage.

Ammonia Removal Oxidation ditches can be set up to remove ammonia very effectively. Wastewater can be sent through two sets of ditches, each of which has a different pH. The different pH in the two ditches creates a niche for certain microorganisms. These microorganisms are very efficient at removing B.O.D and converting ammonia to nitrates. Oxidation ditches are much more efficient at ammonia removal than packaged plants.

Dissolved Air Flotation (D.A.F)

Flotation process (sometimes called flotation separation) is a method of separation widely used in the wastewater treatment and mineral processing industries.

Various flotation processes include the following:

§ Dissolved air flotation

§ Induced gas flotation

§ Froth flotation, typical in the mineral processing industry.

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device. (1). (2), (3).

Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities. A very similar process known as induced gas flotation is also used for wastewater treatment. Froth flotation is commonly used in the processing of mineral ores.

In the oil industry, dissolved gas flotation (DGF) units do not use air as the flotation medium due to the explosion risk. Natural gas is used instead to create the bubbles.

A portion of the clarified effluent water leaving the DAF tank is pumped into a small pressure vessel (called the air drum) into which compressed air is also introduced. This results in saturating the pressurized effluent water with air. The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction valve just as it enters the front of the float tank, which results in the air being released in the form of tiny bubbles.

Various flotation processes include the following:

§ Dissolved air flotation

§ Induced gas flotation

§ Froth flotation, typical in the mineral processing industry.

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device. (1). (2), (3).

Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities. A very similar process known as induced gas flotation is also used for wastewater treatment. Froth flotation is commonly used in the processing of mineral ores.

In the oil industry, dissolved gas flotation (DGF) units do not use air as the flotation medium due to the explosion risk. Natural gas is used instead to create the bubbles.

Reference:

1. Beychok,

Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st ed.).

John Wiley & Sons. LCCN 67019834.

2. Lawrence

3. Kiuru, H.; Vahala, R., eds (2000). "Dissolved air flotation

in water and waste water treatment". International conference on DAF in water and

waste water treatment No. 4, Helsinki, Finland. IWA Publishing, London

The feed water to the DAF float tank is often (but not always) dosed with a coagulant (such as ferric chloride or aluminum sulfate) to flocculate the suspended matter.A portion of the clarified effluent water leaving the DAF tank is pumped into a small pressure vessel (called the air drum) into which compressed air is also introduced. This results in saturating the pressurized effluent water with air. The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction valve just as it enters the front of the float tank, which results in the air being released in the form of tiny bubbles.

The bubbles adhere to the suspended matter, causing the suspended matter to float to the surface and form a froth layer which is then removed by a skimmer. The froth-free water exits the float tank as the clarified effluent from the DAF unit.

Reference:(Beychok, Milton R.

(1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st ed.).

John Wiley & Sons. LCCN 67019834)

Some DAF unit designs utilize parallel plate packing material, lamellas, to provide more separation surface and therefore to enhance the separation efficiency of the unit. DAF can be categorized by Circular (more efficient) and Rectangular (more residence time). The former type requires just 3 minutes and the example is Wockoliver DAF system, whereas Rectangular requires 20 to 30 minutes the typical example can be syskill DAF system. One of the bigger advantage of Circular is its Spiral Scoop.

Operating Principle

Air under pressure is dissolved into water according to Henry's Law of Dissolution. Releasing the pressure back to STP via a special device creates millions of microbubbles approximately 30-100 microns in diameter. The microbubbles attach to floc in the water and float it to the surface for removal.

Features

High Loading - Rates 4-6 gpm/sf.

Reduced Chemical Comsumption - Formation of a large, rapidly settling floc is not required, saving money.

High Sludge Concentrations - Dewatering can occur without additional thickening, eliminating expensive sludge thickeners.

Rapid Start-Up - Good-quality water can be produced within 45 minutes of start-up.

Compact Design - Requires less space than conventional processes.

Secondary Treatment;

Attached growth; - trickling filter

A trickling filter consists of a fixed bed of rocks, lava, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (bio-film) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced air flowing through the bed or natural convection of air if the filter medium is porous. The terms trickle filter, trickling biofilter, biofilter, biological filter and biological trickling filter are often used to refer to a trickling filter. These systems have also been described as roughing filters, intermittent filters, packed media bed filters, alternative septic systems, percolating filters, attached growth processes, and fixed film processes.

Sewage treatment trickle filters Attached growth; - trickling filter

A trickling filter consists of a fixed bed of rocks, lava, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (bio-film) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced air flowing through the bed or natural convection of air if the filter medium is porous. The terms trickle filter, trickling biofilter, biofilter, biological filter and biological trickling filter are often used to refer to a trickling filter. These systems have also been described as roughing filters, intermittent filters, packed media bed filters, alternative septic systems, percolating filters, attached growth processes, and fixed film processes.

Onsite sewage facilities (OSSF) are recognized as viable, low-cost, long-term, decentralized approaches to sewage treatment if they are planned, designed, installed, operated and maintained properly (USEPA, 1997).

Sewage trickling filters are used in areas not serviced by municipal wastewater treatment plants (WWTP). They are typically installed in areas where the traditional septic tank system are failing, cannot be installed due to site limitations, or where improved levels of treatment are required for environmental benefits such as preventing contamination of ground water or surface water.

Sites with a high water table, high bedrock, heavy clay, small land area, or which require minimal site destruction (for example, tree removal) are ideally suited for trickling filters.

All varieties of sewage trickling filters have a low and sometimes intermittent power consumption. They can be somewhat more expensive than traditional septic tank-leach field systems, however their use allows for better treatment, a reduction in size of disposal area, less excavation, and higher density land development.

Industrial wastewater treatment trickle filters

Wastewaters from a variety of industrial processes have been treated in trickling filters. Such industrial wastewater trickling filters consist of two types:

Large tanks or concrete enclosures filled with plastic packing or other media.[1]

Vertical towers filled with plastic packing or other media.[2][3]

The availability of inexpensive plastic tower packings has led to their use as trickling filter beds in tall towers, some as high as 20 meters.[4] As early as the 1960s, such towers were in use at: the Great Northern Oil's Pine Bend Refinery in Minnesota; the Cities Service Oil Company Trafalgar Refinery in Oakville, Ontario and at a kraft paper mill.[5]

The treated water effluent from industrial wastewater trickling filters is very often subsequently processed in a clarifier-settler to remove the sludge that sloughs off the microbial slime layer attached to the trickling filter media (see Image 1 above).

Currently, some of the latest trickle filter technology involves aerated biofilters which are essentially trickle filters consisting of plastic media in vessels using blowers to inject air at the bottom of the vessels, with either downflow or upflow of the wastewater.[6]

References

General : Trickling filter wastewater treatment systems were once used primarily for secondary biological treatment. Since typical effluent characteristics do not meet today's strict effluent limitations, many systems have concerted to activated sludge. Attached growth systems still have application today when coupled with a suspended growth option.

Advantages of TF Systems : (a) simplicity of operation, (b) resistance to shock loads, (c) low sludge yield and (d) low power requirements.

Disadvantages of TF Systems : (a) relatively low BOD removal (85%), (b) high suspended solids in the effluent (20 - 30 mg/L) and (c) little operational control.

Standard Rate and High Rate Trickling Filter : Classification of trickling filters is usually based on organic and hydraulic loadings. Standard rate filters see a hydraulic loading of 25 - 100 gpd/ft2 and an organic loading of 15 - 30 lbs BOD/day/1,000 ft3. Loading greater than this will put the filter into the high rate category. Generally the higher the loading the lower the treatment (lower BOD removal). The higher the organic loading the faster the biomass growth to a point. Nitrification usually occurs in the standard rate system.

Synthetic Media : Synthetic media in a trickling filter system results in a greater surface area available for biological growth per cubic foot of filter volume. Because of the low weight of synthetic media, filters can be built 40 ft and higher. The result is the ability to handle greater loadings.

High Void Ratio : Void ratio refers to the physical openings in the media for water and solids to pass. A higher void ratio allows for a greater hydraulic loading and makes the media less susceptible to plugging.

Oxygen Transfer and Detention Time : The design of synthetic media (especially crossflow) provides for greater turbulence at the surface of the media. This greater turbulence promotes oxygen transfer. The greater the surface are per cubic foot of media, the longer it takes for the water to "trickle" through the filter. Synthetic media with 25 - 75 ft2/ft3 provide long detention times.

Objectives of Trickling Filter Recirculation : (a) reduce strength of filter influent, (b) maintain constant wetting rate, (c) force sloughing to occur, increase shear forces, (d) dilute toxic wastes, (e) reseed the filter and (f) increase air flow. Series and Parallel Flow : Parallel flow of a two-stage trickling filter system provides the greatest surface are in the first step of treatment. Parallel flow for high hydraulic and/or organic loadings. Series flow buys more treatment time. Shift to series for nitrification.

Nitrification in Trickling Filters: Nitrification occurs under the same environmental conditions as activated sludge treatment systems. Low hydraulic loadings (standard rate), warm temperatures and long detention times (series flow or synthetic media) promote nitrification. In trickling filter systems, the SBOD must be less than 20 mg/L for nitrification to occur.

Phosphorus Removal: Some of the soluble phosphorus is removed when the BOD is removed by the biomass. Additional phosphorus removal would have to take place in a separate tank. Either chemical precipitation or a suspended growth system with an anaerobic tank would be needed.

SBOD: Soluble BOD is usually the test of choice for operational control of any attached growth treatment system. To get a true measure of the BOD removal, the particulate material (sloughed biomass) must be removed from the sample. SBOD measures the dissolved organics that need to be removed by the biomass.

Combination Systems : Combination systems such as TF/SC, TF/AS, and filtration systems are used to clean up the effluent from the attached growth system. This takes advantage of the trickling filter's capability but still provides final effluent to meet a 10/10 effluent permit.

Suspended Growth vs. Attached Growth Septic Systems: Oxygen-supported (aerobic) bacteria in the mixed liquor perform the primary treatment in the system. As the bacteria themselves die off they remain suspended in the mixed liquor - a "suspended growth aerobic treatment system". Alternatively, a media, such as synthetic fabrics, may be suspended in the treatment tank, permitting the bacteria to attach to the media surfaces - an "attached growth aerobic treatment system". Saturated vs. Non-Saturated Wastewater Treatment Systems: An aerobic treatment unit (ATU), because it involves a tank filled with wastewater and forced oxygenation of that wastewater, is a type of saturated wastewater treatment system. Other non-saturated wastewater treatment systems such as trickling filter beds use passively-infused air to support their oxygen-supported microorganisms. Unlike ATUs, non-saturated systems allow passive air contact with effluent as it moves through the media. Air is not being pumped. Both types of systems make use of aerobic microorganisms.

· Low production of biological sludge.

· High treatment efficiency, up to 90% COD removal.

· Low capital cost, the reactor is essentially a tank.

· No oxygen requirement, hence low power consumption.

· Methane production is a potential source of fuel.

· Low nutrient requirement.

· Low operating costs

Disadvantage of the Anaerobic Process

Sensitive to temperature of influent, works best at about 35 - 40 deg C

· Sensitive to pH, works best at 6.5 – 7.8.

· Treatment efficiency diminishes as the influent COD reduces.

· Does not completely eliminate COD. Requires a secondary process.

· Methane gas may be a liability if no user available.

Solubility of metals hydroxides vs pH The solubility of the hydroxide precipitation is too high, pollution residues after this treatment is much too high. Another disadvantage with the method is the fact that that the solubility of metal hydroxide strongly depends on pH. Different metal hydroxides show solubility minima at different pH-values (see diagram). This implies that an efficient precipitation of a single metal can only be achieved in a very narrow pH-range. This makes precipitation more difficult especially in the presence of complexers such as EDTA, acid wine or lemon acid in waste water. For heavy metal water of various composition this demands multistage precipitation leading to high costs. Hydroxide precipitations of this kind are often gelatinous and difficult to remove by filters. Hydroxide precipitation is therefore often combined with ion changers, reversed osmosis, or electro- dialyse. Processes of this kind, however, are linked with high investment costs. Furthermore they do not manage major load variations.

1.

King Fahd University of Petroleum and Minerals, Course

ChE 101.11 Saudi

Aramco Engineering Development Program, pages 62-65 including Figure 11

2.

Biological filter and process U.S.

3.

Lecture by

Dr. Allen Davis, Auburn University, page 6 of 8 pdf pages

including schematic of packed tower trickling filter)

4. Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st

Edition ed.). John Wiley & Sons Ltd. LCCN

67019834.

5. E.H.

Bryan and D.H. Moeller, Aerobic

Biological Oxidation Using Dowpac, Paper 42, Conference on Biological Waste

Treatment, Manhattan College, April 20, 1960. [1] ^ Marcus Van Sperling (2007). Activated Sludge and

Aerobic Biofilm Reactors. IWA Publications. ISBN 1-84339-165-1.

Advantages of TF Systems : (a) simplicity of operation, (b) resistance to shock loads, (c) low sludge yield and (d) low power requirements.

Disadvantages of TF Systems : (a) relatively low BOD removal (85%), (b) high suspended solids in the effluent (20 - 30 mg/L) and (c) little operational control.

Standard Rate and High Rate Trickling Filter : Classification of trickling filters is usually based on organic and hydraulic loadings. Standard rate filters see a hydraulic loading of 25 - 100 gpd/ft2 and an organic loading of 15 - 30 lbs BOD/day/1,000 ft3. Loading greater than this will put the filter into the high rate category. Generally the higher the loading the lower the treatment (lower BOD removal). The higher the organic loading the faster the biomass growth to a point. Nitrification usually occurs in the standard rate system.

Synthetic Media : Synthetic media in a trickling filter system results in a greater surface area available for biological growth per cubic foot of filter volume. Because of the low weight of synthetic media, filters can be built 40 ft and higher. The result is the ability to handle greater loadings.

High Void Ratio : Void ratio refers to the physical openings in the media for water and solids to pass. A higher void ratio allows for a greater hydraulic loading and makes the media less susceptible to plugging.

Oxygen Transfer and Detention Time : The design of synthetic media (especially crossflow) provides for greater turbulence at the surface of the media. This greater turbulence promotes oxygen transfer. The greater the surface are per cubic foot of media, the longer it takes for the water to "trickle" through the filter. Synthetic media with 25 - 75 ft2/ft3 provide long detention times.

Objectives of Trickling Filter Recirculation : (a) reduce strength of filter influent, (b) maintain constant wetting rate, (c) force sloughing to occur, increase shear forces, (d) dilute toxic wastes, (e) reseed the filter and (f) increase air flow. Series and Parallel Flow : Parallel flow of a two-stage trickling filter system provides the greatest surface are in the first step of treatment. Parallel flow for high hydraulic and/or organic loadings. Series flow buys more treatment time. Shift to series for nitrification.

Nitrification in Trickling Filters: Nitrification occurs under the same environmental conditions as activated sludge treatment systems. Low hydraulic loadings (standard rate), warm temperatures and long detention times (series flow or synthetic media) promote nitrification. In trickling filter systems, the SBOD must be less than 20 mg/L for nitrification to occur.

Phosphorus Removal: Some of the soluble phosphorus is removed when the BOD is removed by the biomass. Additional phosphorus removal would have to take place in a separate tank. Either chemical precipitation or a suspended growth system with an anaerobic tank would be needed.

SBOD: Soluble BOD is usually the test of choice for operational control of any attached growth treatment system. To get a true measure of the BOD removal, the particulate material (sloughed biomass) must be removed from the sample. SBOD measures the dissolved organics that need to be removed by the biomass.

Combination Systems : Combination systems such as TF/SC, TF/AS, and filtration systems are used to clean up the effluent from the attached growth system. This takes advantage of the trickling filter's capability but still provides final effluent to meet a 10/10 effluent permit.

Suspended Growth vs. Attached Growth Septic Systems: Oxygen-supported (aerobic) bacteria in the mixed liquor perform the primary treatment in the system. As the bacteria themselves die off they remain suspended in the mixed liquor - a "suspended growth aerobic treatment system". Alternatively, a media, such as synthetic fabrics, may be suspended in the treatment tank, permitting the bacteria to attach to the media surfaces - an "attached growth aerobic treatment system". Saturated vs. Non-Saturated Wastewater Treatment Systems: An aerobic treatment unit (ATU), because it involves a tank filled with wastewater and forced oxygenation of that wastewater, is a type of saturated wastewater treatment system. Other non-saturated wastewater treatment systems such as trickling filter beds use passively-infused air to support their oxygen-supported microorganisms. Unlike ATUs, non-saturated systems allow passive air contact with effluent as it moves through the media. Air is not being pumped. Both types of systems make use of aerobic microorganisms.

Suspended growth;

Aeration tank

How Do Aerobic Treatment Units Work?

By bubbling compressed air through liquid effluent in a tank, ATUs create a highly oxygenated (aerobic) environment for bacteria, which uses the organic matter as an energy source. In another stage bacteria and solids settle out of the wastewater and the cleaner effluent is distributed to a soil treatment system. ATUs are more complicated than septic tanks. In a septic tank, solids are constantly separating from liquid. As individual bacterial cells grow, they sink to the bottom, along with less decomposed solids, to form a layer of sludge. Floating materials, such as fats and toilet paper, form a scum layer at the top of the tank.

Aeration tank

How Do Aerobic Treatment Units Work?

By bubbling compressed air through liquid effluent in a tank, ATUs create a highly oxygenated (aerobic) environment for bacteria, which uses the organic matter as an energy source. In another stage bacteria and solids settle out of the wastewater and the cleaner effluent is distributed to a soil treatment system. ATUs are more complicated than septic tanks. In a septic tank, solids are constantly separating from liquid. As individual bacterial cells grow, they sink to the bottom, along with less decomposed solids, to form a layer of sludge. Floating materials, such as fats and toilet paper, form a scum layer at the top of the tank.

In an ATU, the bubbler agitates the water so solids cannot settle out, and floating materials stay mixed in the liquid. Well-designed ATUs allow time and space for settling, while providing oxygen to the bacteria and mixing the bacteria and its food source (sewage). Any settled bacteria must be returned to the aerobic portion of the tank for mixing and treatment.

There are three basic ATU operation styles: suspended growth, fixed-film reactor, and sequencing batch reactor. All three types usually have a septic tank (sometimes called a trash tank) ahead of them that removes the large solids and provides some protection to the ATU.

A suspended-growth tank has a main treatment chamber where bacteria are free-floating and air is bubbled through the liquid. The second chamber where the solids settle out is separated from the main tank by a wall or baffle. The two chambers are connected at the bottom or by a pump, and settled bacteria from the second chamber are brought back into the main treatment chamber. This return and mixing is critical for proper operation. Treated effluent from the second chamber is piped to the soil treatment system. Though simple, the system is likely to have problems with bulking (the formation of chains or colonies of bacteria that don't settle or sink to the bottom as they should). Bulking is caused by changes in wastewater strength or quantity. When too much water/wastewater is added to the system, the bacteria can run out of food or become overloaded. Bulked bacteria remain suspended in the liquid and can clog the outflow. A fixed-film reactor has bacteria growing on a specific surface medium and air is provided to that part of the tank. The bacteria can grow on any surface including fabric, plastic, styrofoam, and gravel. Decomposition is limited to this area, and settling occurs in a second chamber. This design is expensive, but the effluent is of consistently high quality, and bulking is uncommon. There is no need for a return mechanism because the bacteria stay on the film.

There are three basic ATU operation styles: suspended growth, fixed-film reactor, and sequencing batch reactor. All three types usually have a septic tank (sometimes called a trash tank) ahead of them that removes the large solids and provides some protection to the ATU.

A suspended-growth tank has a main treatment chamber where bacteria are free-floating and air is bubbled through the liquid. The second chamber where the solids settle out is separated from the main tank by a wall or baffle. The two chambers are connected at the bottom or by a pump, and settled bacteria from the second chamber are brought back into the main treatment chamber. This return and mixing is critical for proper operation. Treated effluent from the second chamber is piped to the soil treatment system. Though simple, the system is likely to have problems with bulking (the formation of chains or colonies of bacteria that don't settle or sink to the bottom as they should). Bulking is caused by changes in wastewater strength or quantity. When too much water/wastewater is added to the system, the bacteria can run out of food or become overloaded. Bulked bacteria remain suspended in the liquid and can clog the outflow. A fixed-film reactor has bacteria growing on a specific surface medium and air is provided to that part of the tank. The bacteria can grow on any surface including fabric, plastic, styrofoam, and gravel. Decomposition is limited to this area, and settling occurs in a second chamber. This design is expensive, but the effluent is of consistently high quality, and bulking is uncommon. There is no need for a return mechanism because the bacteria stay on the film.

Sequential Batch Reactor (SBR)

In a sequencing batch reactor, aerobic decomposition, settling, and return occur in the same chamber. Air is bubbled through the liquid during the decomposition cycle. The bubbler shuts off, and the wastewater goes through a settling cycle. Once the bubbler turns back on, the tank re-enters the decomposition cycle, and settled bacteria mixes back into the aerobic environment.

After settling of bacteria and solids, the treated effluent is discharged to the soil treatment system. Bacteria settle out more consistently in this kind of tank, but since it has more moving parts and requires a controller, it has more potential for mechanical and electrical failure.

Sludge Volume Index (SVI) is a very important indicator that determines your control or rate of desludging on how much sludge is to be returned to the aeration basin and how much to take it out from the system. It actually serves as a very important empirical measurement that can be used as a guide to maintain sufficient concentration of activated sludge in the aeration basin whereby too much or too little can be considered detrimental to the system’s overall health. To put it in a lay man’s term, desludging or sometimes referred to as recycling sludge process, actually plays a very important role because the whole operation is needed to somehow strike a balance between removing dead or aged bacteria out of the systems or to determine how much goes back to the aeration pond.

SVI can actually be determined through use of standard laboratory test methods to come up with the results. Basically the procedure involves measuring the Mixed Liquor Suspended Solids (MLSS) value and also the sludge settling rate. A simple explanation on how it is carried out can be summarized below with accompanying images for easy reference and better understanding:

Obtain sample of mixed liquor from the pond discharge pipeline and fill it to a 1 liter graduated measuring cylinder until the 1.0 liter marking.

Allow it to settle for 30 minutes

After the time period, read the marking to determine the volume occupied by the settled sludge and the reading is expressed in terms of mL/L and this is figure is known as the SV value.

Next, for MLSS, there are actually two approaches to get the value. A conventional standard approach is by filtering the sludge, drying it and then weigh the second portion of the mixed liquid. However, this can be time consuming and a faster way is by using MLSS meter. Value of Sludge Volume Index can then be calculated from the formula given here. Whereby,

SVI = SV/MLVSS X 1000

SVI = Sludge Volume Index, mL/g

SV = Volume of settled solids in one-liter graduated transparent measuring cylinder after 30 minutes settling period, mL/L

MLSS = Mixed liquor Suspended Solids, ppm

SVI is a key factor when it comes to the clarifier design so that a clear wastewater discharge can be obtained without significant carry over of sludge. Basically what the value represents is the settling characteristics that have profound effect on the return rates and also the MLSS value. Typically a healthy sludge aeration pond basin should have the value registered within 80 to 150 mL/g and the MLSS concentration between 3000 – 5000ppm with the wastewater temperature less than 20degC. With this value in mind, generally the clarifier or settling basin has to be designed to accept higher solid loadings so that loss or carry over of sludge due to hydraulic displacement can be minimized.

Activated sludge pond is designed to allow adjustments on the amount of sludge return and also the take off rate. Regular desludging must be carried out to remove the aged sludge so that the new bacteria can regenerate and allowed to grow. As an experienced operator or engineers that operate the wastewater treatment plant, a tight control must be put in place to adjust the MLSS value to the desired concentration based on the set limit SVI to be used as a guide.

Anaerobic digestion

Principles & application

Anaerobic digestion

Technical Description Many people are concerned about pollution and the management of waste, but for some industries, this problem can become overwhelming. For example how do farmers deal with inevitable daily replenishing of methane-producing manure piles? How do palm-oil millers dispose of large amounts of oily organic wastewater? For these kinds of companies, anaerobic digestion is the best waste management option. Anaerobic digestion transforms waste into useful end-products, removing dangerous pollutants in the process.

Anaerobic wastewater treatment is a process whereby bacteria digests biosolids in the absence of oxygen. One major feature of anaerobic digestion is the production of biogas, which can be used in generators for electricity production or in boilers for heating purposes. This, plus the fact that aerobic wastewater treatment requires a method for the introduction of oxygen into the process, makes anaerobic wastewater treatment generally more cost effective.In a sequencing batch reactor, aerobic decomposition, settling, and return occur in the same chamber. Air is bubbled through the liquid during the decomposition cycle. The bubbler shuts off, and the wastewater goes through a settling cycle. Once the bubbler turns back on, the tank re-enters the decomposition cycle, and settled bacteria mixes back into the aerobic environment.

After settling of bacteria and solids, the treated effluent is discharged to the soil treatment system. Bacteria settle out more consistently in this kind of tank, but since it has more moving parts and requires a controller, it has more potential for mechanical and electrical failure.