This paper displays and discuss environmental issues related to coal-fired power plants in a holistic manner. Summary of applicable legal requirements in Malaysia are provided throughout the chronology of this industrial activity. Presented in public on April 24, 2012 in Impiana KLCC Hotel, Kuala Lumpur, Malaysia as invited speaker for Marlene Insurance Brokers Sdn Bhd in an event for Tenaga Nasional Berhad titled "Seminar On Power Utility Operations & Maintenance Management".

|

| Example chemical structure of coal |

|

| Anthracite (Ibbenbüren, Germany) |

|

| Bituminous coal |

KOTA KINABALU Feb 16 — Sabah has scrapped the controversial coal-fired

power plant in Lahad Datu saying today it will look for alternative energy

sources after a three year-long campaign by environmentalists. “I am pleased to announce that

federal and state governments have agreed to pursue other alternative sources

of energy namely gas to meet Sabah’s power supply needs ” Sabah Chief Minister

Datuk Seri Musa Aman said in a statement released this afternoon “I know there

have been certain objections to the proposed coal powered plant Today is proof

that such objections have not fallen on deaf ears ” The Department of

Environment DOE had rejected the detailed environmental impact assessment DEIA

for the proposed RM1 3 billion 300-MW coal-fired plant in Felda Sahabat in

August last year because many important environmental parameters in the

proposed project were not addressed in the report. (1)

The powdered

coal from the coal mills is carried to the boiler in coal pipes by high

pressure hot air. The pulverized coal

air mixture is burnt in the boiler in the combustion zone.

Generally in modern boilers tangential firing system is used i.e. the coal nozzles/ guns form tangent to a circle. The temperature in fire ball is of the order of 1300 deg.C. The boiler is a water tube boiler hanging from the top. Water is converted to steam in the boiler and steam is separated from water in the boiler Drum. The saturated steam from the boiler drum is taken to the Low Temperature Superheater, Platen Superheater and Final Superheater respectively for superheating. The superheated steam from the final superheater is taken to the High Pressure Steam Turbine (HPT). In the HPT the steam pressure is utilized to rotate the turbine and the resultant is rotational energy. From the HPT the out coming steam is taken to the Reheater in the boiler to increase its temperature as the steam becomes wet at the HPT outlet. After reheating this steam is taken to the Intermediate Pressure Turbine (IPT) and then to the Low Pressure Turbine (LPT). The outlet of the LPT is sent to the condenser for condensing back to water by a cooling water system. This condensed water is collected in the Hotwell and is again sent to the boiler in a closed cycle. The rotational energy imparted to the turbine by high pressure steam is converted to electrical energy in the Generator.

Generally in modern boilers tangential firing system is used i.e. the coal nozzles/ guns form tangent to a circle. The temperature in fire ball is of the order of 1300 deg.C. The boiler is a water tube boiler hanging from the top. Water is converted to steam in the boiler and steam is separated from water in the boiler Drum. The saturated steam from the boiler drum is taken to the Low Temperature Superheater, Platen Superheater and Final Superheater respectively for superheating. The superheated steam from the final superheater is taken to the High Pressure Steam Turbine (HPT). In the HPT the steam pressure is utilized to rotate the turbine and the resultant is rotational energy. From the HPT the out coming steam is taken to the Reheater in the boiler to increase its temperature as the steam becomes wet at the HPT outlet. After reheating this steam is taken to the Intermediate Pressure Turbine (IPT) and then to the Low Pressure Turbine (LPT). The outlet of the LPT is sent to the condenser for condensing back to water by a cooling water system. This condensed water is collected in the Hotwell and is again sent to the boiler in a closed cycle. The rotational energy imparted to the turbine by high pressure steam is converted to electrical energy in the Generator.

Deforestation.

· reduces the content of water in

the soil and groundwater as well as atmospheric moisture;

§ their canopies intercept a proportion of precipitation, which is then evaporated back to the atmosphere (canopy interception);

§ their litter and other organic residue

change soil properties that affect the capacity of soil to store water.

their

leaves control the humidity of the

atmosphere by transpiring. 99% of the water absorbed by the roots moves up

to the leaves and is transpired.

Legal

liability

· Mountain-top

deforestation for mining purposes in Malaysia is subjected to EIA as classified

under Forestry as “ Conversion

of hill forest land to other land use covering an area of 50 hectares or more.”

Or under Order-2, Environmental Quality (Prescribed Activities)

(Environmental Impact Assessment) Order, 1987. The ‘Schedule’.

· Mining

as “Mining of minerals in new area where the mining lease covers a total area

in excess of 250 hectares.” – Order-2, Environmental Quality

(Prescribed Activities) (Environmental Impact Assessment) Order, 1987. The

‘Schedule’.

Judicial liability for not providing the EIA report as projects gets

underway is RM100,000.00 and/or 5 years imprisonment.

Mountains are geological structures that serves as the

strongest civil structure that holds

the earth crust. They are rocks of

different formation and composition

that emerged from their respective plates

that forms the earth surface. Mountain ranges form in a process called orogenesis, where two tectonic plates

meet.(34)

By nature they are

dynamic and thus unstable as natural

forces are constantly applying pressure

from below its geological settings. However, science haven’t finish learning

about them and can’t make much accurate prediction of their behaviour. Nonetheless,

their desirable constituents to man

are known and named. They include minerals

and metals like palladium, titanium,

uranium (4)(5), gold etc., and of cause oil

and coal. Coal mining generates significant

additionally independent adverse environmental

health impacts, among them the water

pollution flowing from mountaintop removal mining.(2)

§ Impact of water use on flows of rivers and consequent impact on other land uses;

§ Dust;

§ Tunnels sometimes damage infrastructure

(e.g. roads);

§ Land rendered unsuitable for other use.

|

| Entitles for EiMAS CPD Hours:12 (EiMAS/2016/CPD395/1 dated 3rd Feb 2016) Kindly email for full brochure and registration form at sekitar5221@gmail.com |

Pollutants for which indirect exposure is especially important

include mercury, arsenic, dioxins,

cadmium and lead. Mercury

contamination of fish (and subsequent consumption by humans) is the cause of fish

consumption advisories in 40 states for inland waters and advisories for some

saltwater species in 10 states.(3)There are a number of adverse environmental effects of coal mining and burning, specially

in power stations including: Generation of hundreds of millions of tons of

waste products, including fly ash, bottom ash, flue gas desulfurization sludge,

that contain mercury, uranium, thorium, arsenic, and other heavy

metals.(4)Trace elements of uranium. All but 16 of the 92

naturally occurring elements have been detected in coal, mostly as trace

elements below 0.1 percent (1,000 parts per million, or ppm). A study by DOE's Oak Ridge National Lab found that radioactive emissions from coal combustion are greater than those from nuclear

power production.(5)

We have heard about a

fatal accident explosion at a coal

mine in central China that killed 26

miners in Dec 08, 2010. They were working despite an order to halt

production. And, a mine tunnel collapse

elsewhere left four dead in the latest accidents to strike the country’s mining

industry.

Technical and economic feasibility are evaluated based on: regional

geologic conditions; overburden characteristics; coal seam continuity,

thickness, structure, quality, and depth; strength of materials above and below

the seam for roof and floor conditions; topography (especially altitude and

slope); climate; land ownership as it affects the availability of land for

mining and access; surface drainage patterns; ground water conditions;

availability of labor and materials; coal purchaser requirements in terms of

tonnage, quality, and destination; and capital

investment requirements.(6)

Surface mining and deep underground

mining are the two basic methods of mining. The choice of mining method depends

primarily on depth of burial, density of the overburden and thickness of the coal seam. Seams

relatively close to the surface, at depths less

than approximately 180 ft (50 m), are usually surface mined. Coal that

occurs at depths of 180 to 300 ft

(50 to 100 m) are usually deep mined, but in some cases surface mining

techniques can be used. For example, some western U.S. coal that occur at

depths in excess of 200 ft (60 m) are mined by the open pit methods, due

to thickness of the seam 60–90 feet (20–30 m). Coals occurring below

300 ft (100 m) are usually deep mined.(7)

Surface coal mining

with valley fills has impaired the

aquatic life in numerous streams in the Central Appalachian Mountains. Our

results show that mining activity has had subtle to severe impacts on benthic

macroinvertebrate

communities and that the biological condition most strongly correlates with a gradient

of

ionic strength.(8)

Legal

liability

v Coal transport railway:

its construction is subjected to the EIA

requirements as classified under activity ‘Railways’

covering a) Construction of new

routes and b) Construction of branched lines.

Port facility: its construction is its construction is subjected to the EIA requirements as classified under activity ‘Ports’ covering Construction of ports

and Port expansion involving an increase of 50% or more in handling capacity

per annum.

‘When coal

cargo oxidises, it spontaneously generates heat and toxic gases such as

carbon monoxide. This can lead to flammable

atmospheres in the hold, depletion of oxygen in those spaces and corrosion of

metal structures. Lower quality coals such as lignite are more prone to this process than higher quality coals

such as anthracite. Understanding

the quality of coal being shipped and how to monitor it is fundamental to

reducing the risk of self-heating, and possibly the outbreak of fire.’(9)

‘A Chinese coal-carrier, the Shen Neng 1, loaded with 65,000 tonnes of coal and 975

tonnes of fuel oil, ran aground on the Great

Barrier Reef over Easter. The 230-metre ship, on its way from

Gladstone to China, strayed from authorised shipping channels into a restricted

zone and hit Douglas Shoal, near Rockhampton, at full speed.’(10)

Transporting coal produces significant

quantities of air pollution and other environmental problems. Diesel trucks,

trains, and barges which transport

coal all emit toxic chemicals, such

as nitrogen oxide and particulates, which pose serious public health risks. According to a National

Resources Defense Council study, railroad engines and trucks hauling coal

together release more than 600,000 tons of nitrogen oxide and 50,000 tons of

particulate matter into the air every year, mostly in diesel exhaust.(11)

The environmental impact of shipping includes greenhouse gas emissions and oil pollution. Carbon

dioxide emissions

from shipping is currently estimated at 4

to 5% of the global total, and estimated by the International Maritime Organisation (IMO)

to rise by up to 72% by 2020 if no action is taken.(12)

Legal

liability

Additionally, it is also worthwhile

to check issues pertainning to legal

liabilities for any untoward but

probable marine accidents or

incidents that may cause coal to contaminate marine waters. Marine waters are

legally classified into ‘international waters’ or ‘nations’ waters’. In high seas

or international waters ship owners

or transporters and its underwriters are exposed to the Law of The Sea. When the vessel or barge enters within 200 nautical miles of any states, the Exclusive Economic Zone Act, 1984 is applied. And, as it enters

within 12 nautical miles of the

state’s lowest tide shore line they are within the state’s full jurisdiction

under their respective state’s marine and/or environmental legislation. The

contamination of Malaysian marine waters are stipulated under The Environmental Quality Act, 1974

(EQA’74) – Section 27 and 29 for

‘waste, oil and sludge’ which carries a maximum penalty of RM500,000.00 and/or

5 years imprisonment.

Leachate

emanating from a coal-storage area

at an electricutility plant in Northwest Indiana (U.S.A.) is impacting groundwater quality. This

assessment is based on results of a long-term groundwater monitoring program

conducted at Purdue University's Wade

Utility Plant where a monthly average of 32,000 metric tons of both high- and low-sulfur coal are stored.(13)

Pulverizer is a mechanical device for the grinding of many different types of

materials. Types of Pulverisers: Ball

and Tube mills; Ring and Ball

mills; MPS; Ball mill; Demolition. Raw

material enters the top of the pulverizer through the raw material feed pipe.

The raw material is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom

of the pulverizing chamber to remove unwanted moisture and transport the

material dust up through the top of the pulverizer and out the exhaust pipe directly to the burner. Material that has not been

pulverized into fine enough particles cannot be blown out of the top of the

unit; it falls back to the ring and roll to be further pulverized.

Environmental

Issues

·

Dusts;

Although dust sizes are still far larger than 10 um i.e. above 70um, it still pose a threat

especially during plant shut-down and start-up. “Major environmental risk in

coal pulverizer operation is known to be explosion.

The main explosion hazard associated with a pulverizer is related to start-up and shut-down procedures. When a system goes down under load, all the

coal falls out of suspension. The

internal surfaces are at elevated temperatures and the process of spontaneous combustion begins

immediately.”(15)

·

Noise;

According to a report by SENES Consultants Limited titled NOISE ASSESSMENT

STUDY BRANDON GENERATING STATION quoted: “When in operation, the noise from the

boiler, coal pulverizers, pumps

and fans are the dominant noise

sources inside the building, with pulverizers

and Station air compressor being the chief sources on the main floor and the boiler on

the higher floors.

·

Vibration;

On paper it’s all about observing technical specifications, but, in practice a

different ball game comes to play – cost! Maintenance

should not be compromised with cost.

A report showed that inaccurate parts

replacement in pulverizers has led to excessive vibration. “Normal bearing vibration should be less than .10 IPS velocity.

Vibration data collection and monitoring was conducted over several days and it

was found that the vibration level would change from one startup to the next”

.... “used the incorrect bearing outer race measurement”(16)

·

Heat is convected from

pipes and metal surfaces that embodied the equipment continuously and dispersed

constantly within the process area or building;

Dryers: they are used in order to remove the excess moisture from coal which are

usually wetted during transport. As the presence

of moisture will result in fall in efficiency due to incomplete combustion and

also result in CO emission. The Coal-In-Tube

Dryer (CIT) technology enables operating parameters such as pressure and rotating speed

can be automatically determined in response to inlet coal moisture and

throughput in order to maintain the desired outlet moisture. Optimum moisture is needed

to facilitate a kind of ‘wet oxidation’ that enhance combustibility.

Environmental Issue:

·

‘Fugitive dust’ that escape through

pin-holes or cracks at joints and bends; since the acidic nature, abrasive

power and speed is an attrition to metal parts and pipes;

·

Heat is released

continuously and dispersed constantly within the process area or building;

·

Solid wastes; are usually broken

equipments and parts;

·

Material spillage; spill-over from

loose conveyor belts;

·

Oil spillage; from leaking oil

sumps, gear-box, pumps, etc.

·

Noise; from conveyors

transfer-drops, mechanical moving parts, etc.

Legal Liability

·

‘Fugitive dust’; are not measurable

as ‘point-source’ emission. But, experiences from root-cause-analyses derived from ambient air quality data that showed marked higher readings on Total

Suspended Particulates (TSP), have narrowed down to this equipment system

as one of the sources.

·

Heat; is not regulated

under the EQA’74 for its thermal impact but may be covered in occupational

health and safety provisions.

·

Solid wastes; Only when these

broken parts are contaminated with lubricating or hydraulic oil or other

sheduled waste would they be rendered as scheduled waste: SW 422 - A mixture of scheduled and

non-scheduled wastes

·

Material spillage; Coal granules are

not subjected to the EQA’74 but if it remained to be evident as contaminating

the soil then the operation is

liable under Section 24, Environmental Quality Act, 1974

that

prohibit soil contamination.

·

Oil spillage; If they are

recovered and contained then they are regarded as scheduled waste under SW

408 - Contaminated soil, debris or matter resulting

from cleaning-up of a spill of chemical, mineral oil or scheduled wastes, otherwise,

the contaminated area shall pose as an evidence of soil contamination and

liable to Section 24, Environmental Quality Act, 1974.

Noise; its permitted level shall conform to the limits allowed by the DOE under their EIA Approval terms and conditions as measured usually at the

premise’s boundary perimeters.

Magnetic separators: Coal

which is brought in may contain contaminants like iron particles. These iron particles may cause unnecessary or

premature wear and tear to mechnical parts of subsequent processes. The iron

particles may include bolts, nuts wire

fish plates etc. So, these undesirable contaminants are removed with the

help of magnetic separators. The ‘cleaner’ coal are transferred to the

storage site usually near the boiler.

“A concentrated stream of the inorganic minerals is withdrawn from the

pulverizer and processed by the magnetic separator.”(17)

Environmental

issue:

v

Dry Magnetic Separator;

Ø

Residues or trapped

impurities retained and later released from the separator.

Ø

Dust of fine particles;

Ø

Solid waste of coarse

particles and granules.

v

Wet Magnetic Separator;

Ø

Wastewater containing

retentate from the separator.

Legal Liability

Ø

‘Residues or trapped

impurities retained and later released from the separator and Solid waste of

coarse particles and granules.’ These waste or their final waste considering posibilities of recovery

efforts, may subscribe to the Environmental Quality (Scheduled Wastes)

Regulations, 2005 under the following possible classification;

§

SW 101 Waste containing arsenic or its

compound; or

§

SW 109 Waste containing mercury or its

compound; or

§

SW 205 Waste gypsum arising from chemical

industry or power plant (need justification);

§

SW 407 Waste containing dioxins or

furans;

§

SW 410 Rags, plastics, papers or filters

contaminated with scheduled wastes;

§

SW 421 A

mixture of scheduled wastes

§

SW 422 A mixture of scheduled and

non-scheduled wastes

Ø

Dust of fine particles are subjected to the law if released prior an

air pollution control equipment such as the Filter Bag or Electrostatic

Precipitator namely the Environmental

Quality (Clean Air) Regulations, 1978 or other restrictions inposed under

their EIA approval’s terms and conditions.

Ø

Wastewater containing

retentate from the separator;

§

SW 204 Sludges

containing one or several metals including chromium, copper, nickel, zinc,

lead, cadmium, aluminium, tin, vanadium and beryllium;

Wastewater

are generally subjected to Environmental Quality (Industrial Effluent)

Regulations, 2009 or otherwise subjected to other specific

requirement by the DOE, including their EIA approval’s terms and conditions.

Environmental

issues

§ Dust and other air impurities;

are supposed to flow into the receiving air pollution control equipment

designed to trap, contain and prevent them from entering the atmosphere. The

supposedly ‘cleaner air’ is released out from the stack and shall conform to

the emission standard set under Environmental Quality

(Clean Air) Regulations, 1978 or, other specific requirement by the DOE, including their EIA

approval’s terms and conditions.

§ Fugitive dust and fly-ash;

escapes from their respective contained equipment and ductings may enter the

surrounding ambience depending on their size, wind velocity and direction and

other geo-metereological factors. The Malaysian Interim Ambient Air Guidelines may be applied as a legal directive.

§ Heat;

or thermal effect into the surrounding air is affecting surrounding environment

but not regulated in the local environmental law. However, heat is known to be conducted through rock structures stretching

from beneath the furnace or kiln and causes an impact to vegetation growing immediately

above the same seam of rock which are located elsewhere.

§ Solid waste – defected or

broken parts; The fact is these parts are

usually contaminated with hazardous deposts mentioned earlier, otherwise, it’s

worth to recover and recycle these metal wastes

§ Slag deposit;

are likely to to subscribe to to the Environmental

Quality (Scheduled Wastes) Regulations, 2005

Bottom ash; that consists of an array of toxic and hazardous

elements are usually handled via a special Ash Management Program as stipulated

under EIA

approval’s terms and conditions and may be classified as

SW 104 Dust, slag, dross or ash containing arsenic,

mercury, lead, cadmium, chromium, nickel, copper, vanadium, beryllium,

antimony, tellurium, thallium or selenium excluding slag from iron and steel

factory

and managed as Scheduled Waste.

Electrostatic

precipitation(18) removes particles

from the exhaust gas stream of an industrial process. Often the process

involves combustion, but it can be any industrial process that would otherwise

emit particles to the atmosphere. Six activities typically take place:

v

Ionization - Charging of

particles;

v

Migration - Transporting the

charged particles to the collecting surfaces; and

v

Collection - Precipitation of

the charged particles onto the collecting surfaces; and

v

Charge Dissipation - Neutralizing the

charged particles on the collecting surfaces; and

v

Particle Dislodging - Removing the

particles from the collecting surface to the hopper; and

v

Particle Removal - Conveying the

particles from the hopper to a disposal point.

The major precipitator components that accomplish

these activities are as follows:

§Discharge Electrodes

Power Components

§ Precipitator Controls

§ Rapping Systems

§ Purge Air Systems

§ Flue Gas Conditioning

§Discharge Electrodes

Power Components

§ Precipitator Controls

§ Rapping Systems

§ Purge Air Systems

§ Flue Gas Conditioning

Environmental Issues:

Ash: collected from the bottom of ESP as trapped ash shall be

subjected to specific Ash Management Program approved by the authorities,

however, it may be classified as SW

104

Dust, slag, dross or ash containing arsenic, mercury, lead, cadmium, chromium,

nickel, copper, vanadium, beryllium, antimony, tellurium, thallium or selenium

excluding slag from iron and steel factory as Scheduled

Waste.

Stack Emission: is subjected to emission standard under the

Environmental Quality (Clean Air) Regulations, 1978 and other legal biding specification listed in

the EIA approval’s terms and conditions.

Risk of fire or

explosion exists in several electrostatic precipitators,

mainly because of the production of CO.(19)

Environmental issue:

· Power generation has been estimated to

be second only to agriculture in being the largest

domestic user of water.

· The U.S. Geological

Survey estimates that thermoelectric plants withdrew 195 billion gallons of

water per day in 2000, of which 136 billion gallons was fresh water.(20)

General numbers for fresh water

usage of different power sources are shown below.(21)

Water usage (gal/MW-h)

|

|||

Power source

|

Low case

|

Medium/Average case

|

High case

|

400 (once-through cooling)

|

400 to 720 (pond cooling)

|

720 (cooling towers)

|

|

300

|

480

|

||

100 (once-through cycle)

|

180 (with cooling towers)

|

||

1,430

|

|||

1,060

|

|||

1,800

|

4,000

|

||

300

|

480

|

||

30

|

|||

.5

|

1

|

2.2

|

|

· To produce and burn

the 1 billion tons of coal America

uses each year, the mining and utility industries withdraw 55 trillion to 75 trillion gallons of water annually, according to

the US Geological Survey.

Researchers at Sandia National Laboratories put

the estimate higher, finding that the typical 500-megawatt coal-fired utility burns 250 tons of coal per hour, using 12 million gallons of water an hour - 300 million gallons a day - for cooling.(22)

Steam turbines have been used predominantly as prime

mover in all thermal power stations. The steam turbines are mainly divided into

two groups: -

1. Impulse turbine

2. Impulse-reaction turbine

The turbine generator consists

of a series of steam turbines interconnected to each other and a generator

on a

common shaft. There is a high pressure turbine at one end,

followed by an intermediate pressure

turbine, two low pressure turbines,

and the generator. The steam at high temperature (536 ‘c to 540 ‘c) and

pressure (140 to 170 kg/cm2) is expanded in the turbine. Steam turbines can be a very reliable

equipment with life over 30 years and overhaul

approximately every 10 years.

However, about 5 percent of the indsutrial and utility turbines experience corrosion and deposition problem. Mostly due to LP blade and blade attachment

(disc rim) corrosion fatigue or stress corrosion failures. (23)

Environmental issues:

v Spent or Used Hydraulic Fluid; are subjected to

legal requirements under Environmental Quality (Scheduled Wastes) Regulations,

2005 - SW

306 Spent hydraulic oil

v Broken Oil Seals and Caskets, including hydraulic fluid pumps, hydraulic actuators,

as well as the solenoids, and servo valves, etc.; are subjected to legal

requirements under Environmental Quality (Scheduled Wastes) Regulations,

2005 - SW

422 A mixture of scheduled and non-scheduled wastes

v Scales and varnish-like deposits; a compositional and

TCLP analysis is recommended prior arriving to a legal conclusion – the result

is useful to determine if its classification is (SW

204 - Sludges containing one or several metals including

chromium, copper, nickel, zinc, lead, cadmium, aluminium, tin, vanadium and

beryllium) or (SW 205 - Waste gypsum

arising from chemical industry or power plant)

v Used Oil Filters; are subjected to

legal requirements under Environmental Quality (Scheduled Wastes) Regulations,

2005 - SW

410

Rags, plastics, papers or filters

contaminated with scheduled wastes.

v Contaminated Gloves & Rags; are subjected to legal requirements under Environmental Quality (Scheduled Wastes) Regulations, 2005 - SW 410 Rags, plastics, papers or filters contaminated with scheduled wastes.

v Broken Metal Blades and other Metal Parts; these engineered

high quality metal parts may be repaired or disposed in most economic manner.

v

Rust Dust; Despite its

associated potential risk to human health, these dust are scattered around the

working area and difficult to collect and contain. In practice mass cleaning

using wet-jet or vacuum machine cleaners are being done and regarded as ‘normal’

utility waste.

Legal Liability

The Scheduled Waste Management carries a maximum

penalty of RM500,000.00 and/or 5 years

in cases when the scheduled waste (SW) are transported by non-DOE-approved SW contractors to destination, facilities or

premises not authorized/licensed to

receive, store, transit, treat or dispose them.

Generator or Alternator

is the electrical end of a turbo-generator set. It is generally known as the

piece of equipment that converts the mechanical energy of turbine into

electricity. The generation of electricity is based on the principle of electromagnetic induction.

Environmental issue:

v Noise; its permitted level shall conform to the limits allowed by the DOE under their

EIA Approval terms and conditions or the overall power plant’s blanket

approval. In many instances a doule standard for the day and night is

imposed. The approval may specify the number of noise level parameters, monitoring

points, sampling frequency and its general location. However, the exact location of these monitoring

points should be based on a throrough ‘Noise-Mapping’

survey with adequate rationalization

based on environmental receptors

fully illustrated in a layout plan and be submitted to the agency for record.

v Vibration;

Despite the absence of specific vibration

monitoring parameters and limits as legal requirement in the EQA’74, the DOE

may opt to adapt foreign standards or guidelines to monitor this element of

environmental impact.

v Cooling

fluid; Generally,

if the type of cooling fluid is the oil-water emulsion then their waste forms are subjected to

legal requirements under Environmental Quality (Scheduled Wastes) Regulations,

2005 – SW 307 Spent

mineral oil-water emulsion or,

if they are specific thermal coolants as in conventional radiators; - SW 327 Waste of thermal

fluids (heat transfer) such as ethylene glycol, otherwise in some cases where the hydraulic fluid acts as coolant; - SW 306 Spent

hydraulic oil. So, a proper identification of the types and nature

is crucial prior notification to the DOE.

v Broken

parts: If any

generator in power plants is regarded

by the DOE as and

electrical-electronic based equipment, its waste/used electrical parts may be

classified as SW

110

- Waste from electrical and electronic assemblies containing components such as

accumulators, mercury-switches, glass from cathode-ray tubes and other

activated glass or polychlorinated biphenyl-capacitors, or contaminated with

cadmium, mercury, lead, nickel, chromium, copper, lithium, silver, manganese or

polychlorinated biphenyl.

Otherwise, most of the metal waste may be more economic for disposal to

conventional metal recyclers.

Legal Liability

v Noise emission – contravention may be regarded

as non-compliance to EIA’s terms and

conditions of approval or the ‘blanket’ approval and may be charged under Section 41 of The EQA’74 with a maximum

liability of RM10,000.00 and/or 2 years

imprisonment. Note: Section 23 on noise pollution is not meant for power plants or other

industrial sources.

The Scheduled

Waste Management carries a maximum penalty of RM500,000.00 and/or 5 years in cases when the scheduled waste (SW)

are transported by non-DOE-approved SW

contractors to destination, facilities or premises not authorized/licensed to receive, store, transit, treat or

dispose them.

Fly ash is

generally captured by electrostatic

precipitators or other particle filtration

equipment before the flue gases reach the chimneys of coal-fired power plants,

and together with bottom ash removed

from the bottom of the furnace is in this case jointly known as coal ash.

Depending upon the source and makeup of the coal being burned, the components

of fly ash vary considerably, but all fly ash includes substantial amounts

of silicon dioxide (SiO2)

(both amorphous and crystalline)

and calcium oxide (CaO),

both being endemic ingredients in many coal-bearing rock

strata.(24)

Flue Gas Desulfurization (FGD) gypsum is also known as scrubber gypsum. FGD gypsum is the

byproduct of an air pollution control system that removes sulfur from the flue

gas in calcium-based scrubbing systems. It is produced by employing forced

oxidation in the scrubber and is composed mostly of calcium sulfate.(25)

However, this waste much sought after by the cement manufacturing industry.

Thus, through a provision called ‘Special

Management of Scheduled Waste’ this waste may have an extended life-cycle

as building materials.

Toxic constituents depend upon the specific coal bed makeup, but may include one or more of

the following elements or substances in quantities from trace amounts to

several percent: arsenic, beryllium, boron, cadmium, chromium, chromium VI, cobalt, lead, manganese, mercury, molybdenum, selenium, strontium, thallium, and vanadium, along with dioxins and PAH compounds.(26)

A 2007 study by the U.S. Environmental Protection

Agency showed more than 60 sites nationwide where coal ash is suspected or has

been proven to have polluted water. Selenium,

a byproduct of the coal processing that can cause fish and bird deformities, was implicated at more than 20 of the

sites, including Belews Lake in North Carolina — a cooling lake for another

Duke Energy power plant.(27)

Legal

Liability

v Effluent

from Wastewater Treatment Plant or IETS: Prior entering the Ash Pond wastewater

from the facility including surface run-offs are in many cases channeled into

the IETS for treatment aimed not only to remove suspended ash-dust solids but

also trace inorganics such as heavy metals and their compounds. The final

discharge is required to comply to any specification laid under their EIA’s Approval Terms and Conditions

and/or the Environmental Quality (Industrial Effluent)

Regulations, 2009. Contravening the later is

subjected to a maximum liability of RM100,000.00 and/or 5 years imprisonment.

v Sludge from IETS:

is very likely a Scheduled Waste thus rendering it to subscribe to Environmental Quality (Scheduled Wastes) Regulations, 2005 – SW 427 Mineral sludges including calcium hydroxide

sludges, phosphating sludges, calcium sulphite sludges and carbonates sludges

v FGD gypsum: is

a Scheduled Waste thus rendering it to subscribe to Environmental Quality (Scheduled Wastes) Regulations, 2005 - SW 205 Waste gypsum arising from chemical industry or

power plant.

v Ash Pond Overflow

discharges: In some recent examples it is

noted that the treated discharges from the Ash Pond is being reused into the

power plant’s facility and its a noteworthy environmental endeavor.

Nonetheless, its discharges into the receiving water body shall conform to Environmental Quality (Industrial Effluent) Regulations, 2009.

Seepage from Ash Pond: Although in the

construction of recent Ash Ponds certain types of ‘non-pemeable’ layers of

materials were deployed, it is still unclear of it’s permeable-proof qualities.

Geo-textiles are not absolutely permeable-proof though.

It is understandable that energy is a basic need of modern life and that power generation

plants have ‘lit’ our daily and nightly lives. Besides power plants are our

other activities that are equally responsible in ‘shaping’ the ‘quality’ of

life. In other words, everything humans

do, including what NGOs are doing too, are

polluting the environment. The issue of debate and dispute then narrows

down to ‘how much and how long’. There is no

absolute solution to pollution. As we think into it, we’d realise that all

these so called ‘pollution prevention

and control’ efforts simply transform

and transfer them. Thus, it is

important to note that whatever we ‘dump’ into the environment are coming back,

not in the form that we dump, but, in the form of our favourite dish! Biological magnification often refers to the process whereby certain

substances such as pesticides or heavy metals move up the food chain, work their way into rivers or lakes, and are eaten by

aquatic organisms such as fish, which in turn are eaten by large birds, animals

or humans. The substances become concentrated

in tissues or internal organs as

they move up the chain. Bioaccumulants are substances that increase in

concentration in living organisms as they take in contaminated air, water, or

food because the substances are very slowly metabolized or excreted. Although

sometimes used interchangeably with 'bioaccumulation,' an important distinction

is drawn between the two, and with bioconcentration, it is also important to

distinct between sustainable development and overexploitation in biomagnification.

§ Bioaccumulation occurs within a trophic level, and is the increase in

concentration of a substance in certain tissues of organisms' bodies due to

absorption from food and the environment.

Thus

bioconcentration and bioaccumulation occur within an organism, and

biomagnification occurs across trophic (food chain) levels. Biodilution is also a process that occurs to all trophic

levels in an aquatic environment; it is the opposite of biomagnification, thus

a pollutant gets smaller in concentration as it progresses up a food web.(28)

KUALA LUMPUR: Malaysia will become a net energy

importer before 2020 and is therefore committed

to find alternative means, Deputy Science, Technology and Innovation Minister

Fadillah Yusof said Tuesday.(29)

Environmentalists and alternative energy producers have criticised the approval for Malaysia’s first nuclear power plant saying it was rushed through without adequate public consultation given the risks of radioactivity.(30)

In

some ways wind power has advantages

over solar photovoltaic generation.

Wind blows day or night, sunny or cloudy, and often it can be at its strongest

potential during the coldest and darkest nights of the winter when it is needed

the most. Wind is created when the sun heats certain areas of the Earth's

surface more than others. This is called differential heating, and it induced

both vertical and horizontal air currents. The patterns of these currents are

modified by the Earth's rotation and the contours of the land. Wind is captured

and converted into energy with the use of a wind turbine such as the one shown

in the diagram. As the wind passes the blades of the tower the rotor will be forced to turn. It is

this motion that will turn a generator, thus producing electricity.(33)

Relevant Data from Wikipedia: http://en.wikipedia.org/wiki/Coal

Author: Khalid Mohd Ariff, 19th March 2012

The Ninth Malaysian Plan (2006-2010) targets 350 MW of

grid-connected renewable electricity by with fuel mix of 40 percent gas, 40

percent coal, 10 percent hydropower and 10 percent renewable energy.

Another major development in the offing is the proposed introduction of

feed-in-tariff for renewable energy in 2011.(31)

FWEPS (Float Wave Electric Power Station) is

one of the promising devices for offshore

wave energy conversion which is being developed. The second technique is

the electrolytic installation intended for hydrogen production by means of sea

water electrolysis followed by usage this ecologically safe fuel in different

branches of economy.(32)

Conclusion

There are numerous damaging environmental impacts of coal that occur through

its mining, preparation, combustion, waste storage, and transport as summarized

as follows:

§

Acid mine drainage (AMD) refers to the

outflow of acidic water from coal mines or metal mines, often abandoned mines

where ore- or coal mining activities have exposed rocks containing the

sulphur-bearing mineral pyrite. Pyrite reacts with air and water to form sulphuric

acid and dissolved iron, and as water washes through mines, this compound forms

a dilute acid, which can wash into nearby rivers and streams.

§

Air pollution from coal-fired power plants includes sulfur

dioxide, nitrogen

oxides, particulate

matter (PM), and heavy metals, leading to smog,

acid rain, toxins in the environment, and numerous respiratory, cardiovascular,

and cerebrovascular effects.

§

Air pollution from coal mines is mainly due to emissions of particulate

matter and gases including methane (CH4), sulfur

dioxide (SO2), and nitrogen

oxides(NOx), as well as carbon

monoxide (CO).

§

Climate impacts of coal plants - Coal-fired power plants are responsible for one-third of America’s carbon

dioxide (CO2) emissions, making coal a huge contributor to global

warming. Black carbonresulting from

incomplete combustion is an additional contributor to climate change.

§

Coal dust stirred up during the mining process, as well as

released during coal transport, which can cause severe and potentially deadly

respiratory problems.

§

Coal fires occur in both abandoned coal mines and coal waste piles. Internationally, thousands of underground coal fires are burning

now. Global coal fire emissions are estimated to include 40 tons ofmercury going into the atmosphere annually, and three percent of the world's annual carbon

dioxide emissions.

§

Coal

combustion waste is the nation's second largest waste stream after municipal solid waste. It is disposed of in landfills or "surface impoundments," which

are lined with compacted clay soil, a plastic sheet, or both. As rain filters

through the toxic ash pits year after year, the toxic metals are leached out

into the local environment.

§

Coal sludge, also known as slurry, is the liquid coal waste

generated by washing coal. It is typically disposed of at impoundments located

near coal mines, but in some cases it is directly injected into abandoned

underground mines. Since coal sludge contains toxins, leaks or spills can

endanger underground and surface waters.

§

Floods such as the Buffalo Creek

Flood caused by mountaintop

removal mining and failures of coal mine impoundments.

§

Forest destruction caused by mountaintop

removal mining - According to a 2010 study, mountaintop removal mining has destroyed 6.8%

of Appalachia's forests.

§

Greenhouse gas emissions caused by

surface mining - According to a 2010 study, mountaintop

removal mining releases large amounts of carbon through clearcutting and burning of

trees and through releases of carbon in soil brought to the surface by mining operations.

These greenhouse gas emissions amount to at least 7% of conventional power

plant emissions.

§

Loss or degradation

of groundwater - Since coal seams are often serve as underground aquifers, removal of

coal beds may result in drastic changes in hydrology after mining has been

completed.

§

Radical disturbance of 8.4 million acres

of farmland, rangeland, and forests, most of which has not been reclaimed --

See The footprint

of coal

§

Heavy metals and coal - Coal contains many heavy metals, as it is created through compressed

organic matter containing virtually every element in the periodic table -

mainly carbon, but also heavy metals. The heavy metal content of coal varies by

coal seam and geographic region. Small amounts of heavy metals can be necessary

for health, but too much may cause acute or chronic toxicity (poisoning). Many

of the heavy metals released in the mining and burning of coal are

environmentally and biologically toxic elements, such as lead, mercury, nickel, tin, cadmium, antimony, andarsenic, as well as radio

isotopes of thorium and strontium.

§

Mercury and coal - Emissions from coal-fired power plants are the largest source of mercury in the United States, accounting for about 41 percent (48 tons in 1999) of

industrial releases.

§

Methane released by coal mining accounts for about 10 percent of US releases of methane (CH4), a

potent global warming gas.

§

Mountaintop removal mining and other forms of surface mining can lead to the

drastic alteration of landscapes, destruction of habitat, damages to water

supplies, and air pollution. Not all of these effects can be adequately

addressed through coal mine

reclamation.

§

Particulates and coal - Particulate matter (PM) includes the

tiny particles of fly ash and dust that are expelled from coal-burning power plants. Studies have shown that exposure to particulate matter is related to an

increase of respiratory and cardiac mortality.

§

Radioactivity and coal - Coal contains minor amounts of the radioactive elements, uranium and

thorium. When coal is burned, the fly ash contains uranium and thorium "at up to 10 times their original

levels."

§

Subsidence - Land subsidence

may occur after any type of underground mining, but it is particularly common

in the case of longwall

mining.

§

Sulfur dioxide and coal - Coal-fired power plants are the largest human-caused source of sulfur

dioxide, a pollutant gas that contributes to the production of acid rain and

causes significant health problems. Coal naturally contains sulfur, and when

coal is burned, the sulfur combines with oxygen to form sulfur oxides.

§

Thermal pollution from coal plants is the degradation of water quality by power plants and industrial

manufacturers - when water used as a coolant is returned to the natural

environment at a higher temperature, the change in temperature impacts

organisms by decreasing oxygen supply, and affecting ecosystem composition.

§

Toxins - According to a

July 2011 NRDC report, "How Power Plants Contaminate

Our Air and States" electricity generation in the U.S. releases 381,740,601 lbs. of toxic air

pollution annually, or 49% of total national emissions, based on data from the

EPA’s Toxic Release Inventory (2009 data, accessed June 2011). Power plants are

the leading sources of toxic air pollution in all but four of the top 20 states

by electric sector emissions.

§

Transportation - Coal is often

transported via trucks, railroads, and large cargo ships, which release air

pollution such as soot and can lead to disasters that ruin the environment, such as the Shen Neng 1 coal carrier collision

with the Great Barrier Reef, Australia that occurred in

April 2010.

§

Waste coal, also known as "culm," "gob," or "boney," is

made up of unused coal mixed with soil and rock from previous mining

operations. Runoff from waste coal sites can pollute local water supplies.[28]

§

Water consumption from coal plants - Power generation has been estimated to be second only to agriculture in

being the largest domestic user of water.

§

Water pollution from coal includes the negative health and environmental effects from the mining,

processing, burning, and waste storage of coal.

Relevant Data from Wikipedia: http://en.wikipedia.org/wiki/Coal

Energy density

Main article: Energy value of coal

The energy density of coal can also be expressed in kilowatt-hours, the units that electricity is most commonly sold in, per units of mass to estimate how much coal is required to power electrical appliances. One kilowatt-hour is 3.6 MJ, so the energy density of coal is 6.67 kW·h/kg. The typical thermodynamic efficiency of coal power plants is about 30%, so of the 6.67 kW·h of energy per kilogram of coal, 30% of that—2.0 kW·h/kg—can successfully be turned into electricity; the rest is waste heat. So coal power plants obtain approximately 2.0 kW·h per kilogram of burned coal.

As an example, running one 100-watt lightbulb for one year requires 876 kW·h (100 W × 24 h/day × 365 day/year = 876000 W·h = 876 kW·h). Converting this power usage into physical coal consumption:

For a coal power plant with a 40% efficiency, it takes 325 kg (714 lb) of coal to power a 100 W lightbulb for one year.[60] One should also take into account transmission and distribution losses caused by resistance and heating in the power lines, which is in the order of 5–10%, depending on distance from the power station and other factors.

Carbon intensity

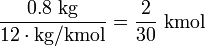

Commercial coal has a carbon content of at least 70%. Coal with a heating value of 6.67 kWh per kilogram as quoted above has a carbon content of roughly 80%, which is

, where 1 mol equals to NA (Avogadro Number) atoms.

, where 1 mol equals to NA (Avogadro Number) atoms.

Carbon combines with oxygen in the atmosphere during combustion, producing carbon dioxide, with an atomic weight of (12 + 16 × 2 = 44 kg/kmol). The CO2 released to air for each kilogram of incinerated coal is therefore

.

.

This can be used to calculate an emission factor for CO2 from the use of coal power. Since the useful energy output of coal is about 31% of the 6.67 kWh/kg(coal),[61] the burning of 1 kg of coal produces about 2 kWh of electrical energy. Since 1 kg coal emits 2.93 kg CO2, the direct CO2 emissions from coal power are 1.47 kg/kWh, or about 0.407 kg/MJ.

The U.S. Energy Information Agency's 1999 report on CO2 emissions for energy generation,[62] quotes a lower emission factor of 0.963 kg CO2/kWh for coal power. The same source gives a factor for oil power in the U.S. of 0.881 kg CO2/kWh, while natural gas has 0.569 kg CO2/kWh. Estimates for specific emission from nuclear power, hydro, and wind energy vary, but are about 100 times lower.

References;

7)

Christman, R.C., J. Haslbeck, B.

Sedlik, W. Murray, and W. Wilson. 1980. Activities, effects and impacts of

the coal fuel cycle for a 1,000-MWe electric power generating plant.

Washington, DC: U.S. Nuclear Regulatory Commission.

8)

Gregory J. Pond et.al., “Downstream effects of mountaintop

coal mining: comparing biological conditions using family- and genus-level

macroinvertebrate bioassessment tools”, Region 3, US Environmental Protection

Agency

13)

Angie M. Cook and Steven J. Fritz “Environmental

Impacts of Acid Leachate Derived from Coal-Storage Piles upon Groundwater”

14)

Ferdinger et.al “Characterization of Organic Material Leached

from Coal by Simulated Rainfall”, in Environmental

Science and Technology, 1989, 23, 170-177

15)

CLETE R.

STEPHAN, P.E.MINE, ‘COAL DUST EXPLOSION HAZARDS’ SAFETY AND HEALTH

ADMININSTRATION PITTSBURGH, PENNSYLVANIA, p.8, year – unknown, p.8

19)

István

Kiss, Tamás Iváncsy, Bálint Németh, István Berta, ‘Advanced Risk Analysis for the

Application of ESP-s to Clean Flammable Gas-pollutant Mixtures’, in 11th International Conference on

Electrostatic Precipitation, pp.50

20)

Lance Frazer, "Low water consumption: a new

goal for coal" in Environmental

Health Perspectives, April, 2004

22)

Sierra Crane-Murdoch, "A Desperate Clinch: Coal

Production Confronts Water Scarcity" Circle of Blue, August 3, 2010

23)

Otakar Jones & Lee

Machemar, ‘Steam Turbines Corrosion and Deposition Problem and Solutions; turbolab.tamu.edu

26)

Source: Managing Coal Combustion Residues in Mines, Committee

on Mine Placement of Coal Combustion Wastes, National Research Council of the

National Academies, 2006; and Human and Ecological Risk Assessment of Coal

Combustion Wastes, RTI, Research Triangle Park, August 6, 2007, prepared for the U.S. Environmental Protection Agency

30)

http://www.themalaysianinsider.com/malaysia/article/nuke-plant-jolts-environmentalists(May 5, 2010)

Author: Khalid Mohd Ariff, 19th March 2012

Reach for the writer Khalid Mohd Ariff

e-mail: sekitar5221@gmail.com

Tel: 019-7725676, +607-2441221

No comments:

Post a Comment